Understanding Global Standards in Circuit Breaker Manufacturing for Optimal Quality and Performance

In today’s rapidly evolving electrical industry, the significance of adhering to global standards in circuit breaker manufacturing cannot be overstated. As the backbone of electrical safety and reliability, circuit breakers accounted for a substantial market size, reaching approximately $8.6 billion in 2022 and projected to grow at a CAGR of 5.4% through 2030, according to a recent industry report. China's remarkable progress in this sector exemplifies how prioritizing quality manufacturing can lead not only to domestic success but also to attaining international respect. By understanding and implementing rigorous global standards, Chinese manufacturers are transforming the circuit breaker landscape, ensuring that their products meet stringent safety and performance benchmarks. This commitment to excellence has positioned China as a formidable player on the world stage, highlighting the vital connection between quality, innovation, and global trust in the intricate world of circuit breakers.

In today’s rapidly evolving electrical industry, the significance of adhering to global standards in circuit breaker manufacturing cannot be overstated. As the backbone of electrical safety and reliability, circuit breakers accounted for a substantial market size, reaching approximately $8.6 billion in 2022 and projected to grow at a CAGR of 5.4% through 2030, according to a recent industry report. China's remarkable progress in this sector exemplifies how prioritizing quality manufacturing can lead not only to domestic success but also to attaining international respect. By understanding and implementing rigorous global standards, Chinese manufacturers are transforming the circuit breaker landscape, ensuring that their products meet stringent safety and performance benchmarks. This commitment to excellence has positioned China as a formidable player on the world stage, highlighting the vital connection between quality, innovation, and global trust in the intricate world of circuit breakers.

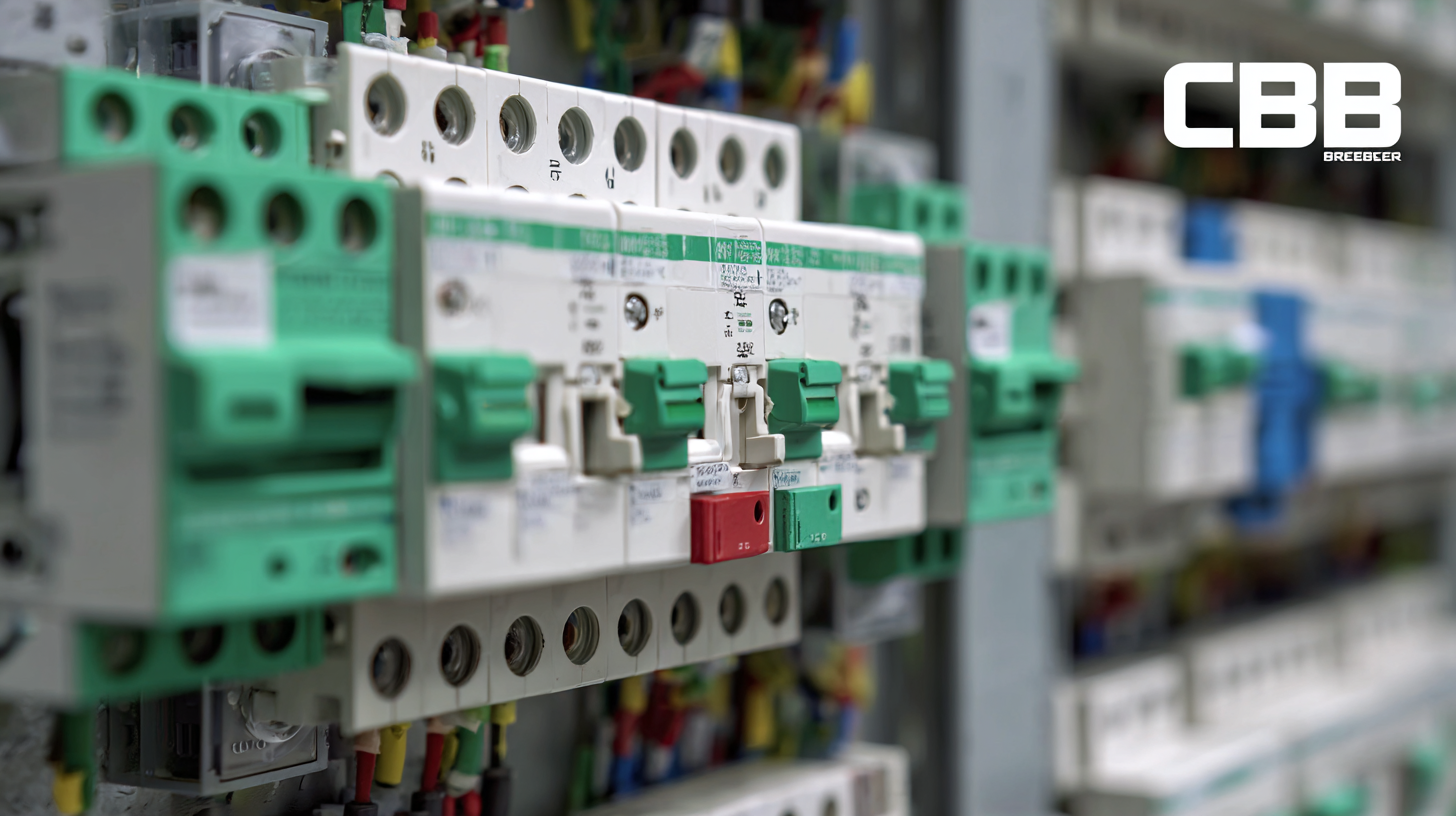

Impacts of Global Standards on Circuit Breaker Manufacturing Techniques

The adherence to global standards in circuit breaker manufacturing plays a pivotal role in shaping industry practices and enhancing product performance. With the global circuit breaker market projected to reach approximately $48.38 billion by 2025, and forecasted to grow significantly to $61.28 billion by 2033, the industry is experiencing a robust compound annual growth rate (CAGR) of 3.0%. This growth underscores the importance of compliance with international standards, which not only streamline production processes but also ensure safety and reliability in electrical systems.

Manufacturers are increasingly adopting innovative techniques and materials to meet these standards, which in turn impact their competitiveness in a cost-sensitive market. For instance, as outlined in industry research, the electric contact materials market is expected to exceed $3.57 billion in sales by 2023 despite facing challenges such as market restrictions and competition. These dynamics highlight the critical need for manufacturers to align their strategies with global regulatory requirements to maintain innovation and drive growth. Emphasizing quality and meeting international standards will ultimately determine the success of circuit breaker manufacturers in the evolving marketplace.

Emerging Technologies Revolutionizing Circuit Breaker Performance

The electrical industry is witnessing a transformative shift thanks to emerging technologies that are enhancing the performance of circuit breakers. Innovations such as smart sensors and IoT connectivity are at the forefront of this revolution. These technologies enable real-time monitoring, allowing circuit breakers to assess their operational health and respond swiftly to potential faults, significantly reducing downtime and improving safety.

Moreover, advancements in materials science are leading to the development of more efficient and durable circuit breakers. New composite materials can withstand higher currents and temperatures while maintaining a compact design. This not only optimizes space in electrical systems but also contributes to overall energy efficiency. Additionally, machine learning algorithms are being employed to analyze operational data, predicting potential failures before they occur and enabling proactive maintenance strategies. These breakthroughs not only ensure reliability but also align with global standards for quality and sustainability in circuit breaker manufacturing.

Sustainability Trends in Circuit Breaker Production for 2025

As the circuit breaker industry looks towards 2025, sustainability is becoming a pivotal focal point in manufacturing processes. According to a recent report by the International Energy Agency, the demand for energy-efficient electrical devices is expected to grow by 25% over the next two years. This trend drives manufacturers to adopt eco-friendly materials and reduce waste throughout the production cycle. By integrating sustainable practices, companies not only enhance their compliance with global standards but also improve their brand reputation and attract environmentally-conscious consumers.

**Tip:** Consider investing in supplier partnerships that prioritize sustainability. By sourcing raw materials from eco-friendly providers, manufacturers can minimize their environmental footprint and promote a circular economy.

Moreover, innovations in recycling processes and the adoption of renewable energy sources are crucial for enhancing the sustainability of circuit breaker production. A report from the World Economic Forum highlighted that around 80% of electrical waste can be effectively recycled, yet many manufacturers still lack comprehensive recycling strategies. As we approach 2025, implementing these strategies can significantly reduce operational costs and support a greener industry.

**Tip:** Regularly evaluate and update your manufacturing processes to incorporate sustainable practices. Staying ahead of regulations will not only ensure compliance but also position your company as a leader in the green revolution in electrical manufacturing.

The Role of Automation in Enhancing Quality Control for Circuit Breakers

In today's rapidly evolving technological landscape, automation plays a crucial role in enhancing quality control within circuit breaker manufacturing. As industries strive to meet ever-stricter global standards for safety and performance, the integration of automated systems has become essential. Research indicates that automation can reduce human errors by up to 70% in manufacturing processes, enabling companies to maintain consistently high quality in their products. Specifically, advanced technologies like robotics and industrial IoT (IIoT) are being incorporated into production lines, allowing for real-time monitoring and precise adjustments that enhance the reliability of circuit breakers.

Furthermore, the shift towards automation is complemented by innovations such as high-speed busbar transfer devices, which improve the responsiveness of power distribution systems, and motor starter protectors that prevent equipment damage by quickly disconnecting power. These advancements not only elevate the performance and safety of circuit breakers but also contribute to overall grid reliability. With automation reshaping the operational landscape, manufacturers are better equipped to deliver products that comply with international regulations while ensuring optimal performance and reducing downtime in utility networks.

Future Challenges in Meeting Global Circuit Breaker Standards and Compliance

As global demand for circuit breakers continues to rise, manufacturers face significant challenges in adhering to ever-evolving standards and compliance requirements. According to a Market Research Future report, the global circuit breaker market is projected to grow at a CAGR of 4.3%, reaching approximately $15 billion by 2025. This surge necessitates that manufacturers not only maintain high production rates but also ensure their products meet various international standards like IEC 60947-2 and UL 489. Failure to comply can result in costly penalties and compromised safety.

Moreover, the transition to renewable energy sources introduces additional complexities in standard compliance. With the increasing integration of smart grid technologies, circuit breakers must be equipped to handle variable loads and enhance system reliability. A report from Technavio highlights that over 30% of circuit breaker manufacturers are investing in R&D to meet these stringent requirements. Achieving compliance with the latest global standards demands innovative solutions and robust quality control measures, ensuring that manufacturers remain competitive while delivering optimal performance and safety in their products.

Understanding Global Standards in Circuit Breaker Manufacturing

This chart illustrates the compliance percentage of different regions with global circuit breaker standards. The data reflects the challenges faced by manufacturers in meeting these standards across various regions.