Exploring the Efficiency and Reliability of Diesel Powered Generators in Emergency Power Supply Systems

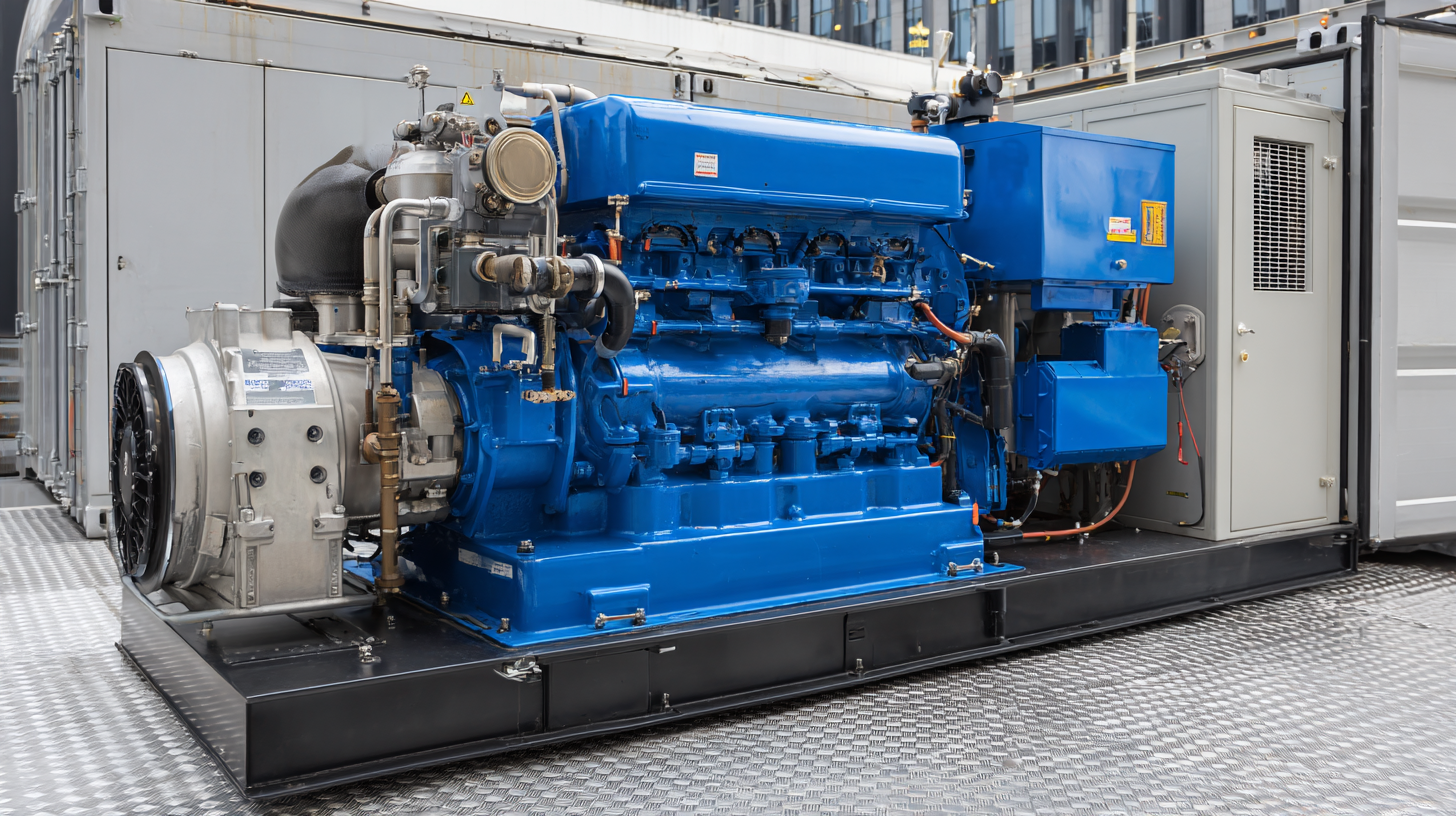

In the realm of emergency power supply systems, the efficiency and reliability of diesel powered generators have become increasingly vital. As the demand for uninterrupted power grows across various sectors, these generators stand out as a robust solution for ensuring operational continuity during power outages. This exploration will delve into the multifaceted advantages offered by diesel powered generators, including their fuel efficiency, durability, and adaptability in various environmental conditions.

Furthermore, the discussion will highlight the importance of these generators in maintaining critical infrastructure, from hospitals to data centers, where uninterrupted power is essential. By examining performance metrics and reliability factors, this inquiry aims to provide a comprehensive understanding of the role that diesel powered generators play in safeguarding against the unpredictability of power supply interruptions.

Furthermore, the discussion will highlight the importance of these generators in maintaining critical infrastructure, from hospitals to data centers, where uninterrupted power is essential. By examining performance metrics and reliability factors, this inquiry aims to provide a comprehensive understanding of the role that diesel powered generators play in safeguarding against the unpredictability of power supply interruptions.

Understanding Diesel Generators: Key Features and Benefits for Emergency Power Supply

Diesel generators are renowned for their robustness and efficiency, making them a preferred choice for emergency power supply systems. One of the key features of diesel generators is their ability to provide a reliable power source during outages, ensuring that critical systems continue to operate. With a longer lifespan compared to other generator types, diesel models can serve businesses and homes effectively in emergencies, providing peace of mind when the grid fails.

Another significant benefit of diesel generators is their fuel efficiency. They can operate for extended periods with minimal refueling, which is crucial during prolonged power outages. Additionally, modern diesel generators are designed with advanced technology that enhances their performance and reduces emissions, making them more environmentally friendly than older models.

Tips: When selecting a diesel generator for emergency power, consider the wattage requirements of your essential appliances to ensure you choose an appropriately sized unit. Regular maintenance is also vital; perform routine checks to ensure your generator is always ready to go when needed. Lastly, investing in soundproofing and proper placement can significantly reduce noise levels, making them suitable for residential areas.

Evaluating Fuel Efficiency: How to Optimize Diesel Generator Performance

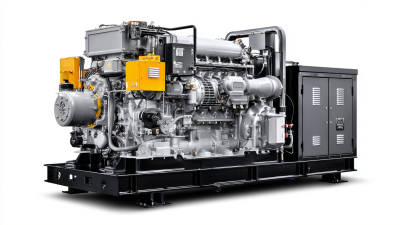

Diesel generators are widely utilized in emergency power supply systems due to their reliability and efficiency. One crucial aspect of their performance is fuel efficiency, which can significantly impact operational costs and environmental sustainability. To optimize the performance of diesel generators, several strategies can be employed, including regular maintenance, proper load management, and the use of high-quality fuels. Regular maintenance ensures that all components function correctly, preventing issues that could lead to increased fuel consumption.

Moreover, understanding and managing the load on the generator is vital. Operating diesel generators at optimal load levels—typically around 70-80% of their rated capacity—can enhance fuel efficiency. When a generator runs underloaded or overloaded, it tends to consume more fuel and experience increased wear and tear. Additionally, selecting the right type of diesel fuel can influence performance, as certain fuels are designed to improve combustion efficiency and reduce emissions. By implementing these measures, users can maximize the efficiency of diesel generators, ensuring they deliver reliable power during emergencies while minimizing operational costs.

Reliability Metrics: Assessing Diesel Generators in Critical Situations

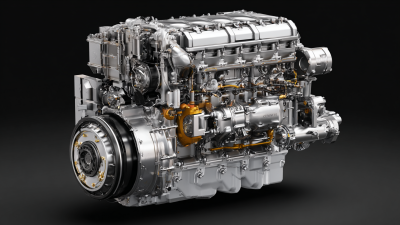

In critical situations, the reliability of diesel generators becomes paramount for ensuring continuous power supply. Reliability metrics play a significant role in assessing the operational performance of these generators during emergencies. Key metrics, such as Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR), provide insights into how often generators fail and the time required for repairs. These metrics enable organizations to make informed decisions about maintenance schedules and replacements, ultimately enhancing system resilience.

Furthermore, the operational efficiency of diesel generators can be evaluated using performance indicators like fuel consumption rates and load capacity. Understanding these factors allows for better planning and utilization of resources during outages. The ability of diesel generators to quickly ramp up to full capacity when unexpected power demands arise is also critical, as delays can lead to detrimental consequences in life-supporting facilities or industrial operations. By systematically analyzing these reliability metrics, organizations can optimize their emergency power supply systems, ensuring they remain capable and effective in times of need.

Maintenance Tips: Ensuring Longevity and Dependability of Diesel Generators

Regular maintenance is crucial for ensuring the longevity and dependability of diesel generators, particularly in emergency power supply systems where reliability is paramount. According to the "Diesel Generator Market Analysis 2023" published by MarketsandMarkets, properly maintained generators can last up to 30% longer than those that are neglected. Key maintenance activities include regular oil changes, air filter replacements, and battery maintenance, which collectively enhance the generator's performance and reduce the likelihood of unexpected failures.

Recognizing the importance of adequate servicing, the National Fire Protection Association (NFPA) recommends a preventive maintenance schedule that encompasses weekly, monthly, and annual checks. This schedule should include inspections of fuel systems for leaks, checks of cooling systems for adequate fluid levels, and routine testing under load conditions. Additionally, utilizing condition monitoring technologies—such as vibration analysis and thermal imaging—can provide early warnings of potential issues, allowing for proactive repairs that fortify the reliability of diesel generators when they are needed most. By implementing these strategies, organizations can ensure that their emergency power supply systems remain efficient and reliable over time.

Safety Protocols: Essential Practices for Operating Diesel Powered Generators

Operating diesel-powered generators in emergency power supply systems requires strict adherence to safety protocols to ensure both efficiency and reliability. According to the U.S. Department of Energy, approximately 70% of all uninterruptible power supply failures are due to human error during operational procedures. To mitigate these risks, it is essential to establish comprehensive safety practices that include regular maintenance checks, proper fuel handling procedures, and efficient troubleshooting techniques.

Furthermore, the Occupational Safety and Health Administration (OSHA) emphasizes the importance of training personnel on the operational aspects and potential hazards of diesel generators. This includes understanding exhaust management, as diesel generators can produce harmful emissions. A recent report from the National Fire Protection Association highlights that nearly 75% of generator-related incidents arise from improper storage and handling of fuel. Therefore, implementing strict protocols for fuel storage, spill management, and emergency shutdown procedures is crucial. By prioritizing these essential practices, organizations can enhance the safety and efficiency of their emergency power supply systems, ultimately ensuring uninterrupted power during critical situations.

Exploring the Efficiency and Reliability of Diesel Powered Generators in Emergency Power Supply Systems - Safety Protocols: Essential Practices for Operating Diesel Powered Generators

| Dimension | Value |

|---|---|

| Generator Type | Diesel |

| Power Output (kW) | 50 - 200 |

| Fuel Consumption (L/h) | 10 - 40 |

| Noise Level (dB) | 75 - 95 |

| Operating Hours (per cycle) | 8 - 24 |

| Maintenance Frequency (months) | 6 - 12 |

| Startup Time (seconds) | 10 - 30 |

| Emissions (g/kWh) | 150 - 250 |

| Safety Features | Automatic Shutdown, Overload Protection |

Related Posts

-

Understanding the Role of Industrial Diesel in Sustainable Energy Transition

-

The Ultimate Guide to Choosing the Right Small Diesel Generator for Your Needs

-

Unleashing Power: How Generator Sets Are Transforming Energy Solutions for Businesses

-

Maximize Your Power Supply: The Unmatched Reliability of Perkins Generators for Every Need

-

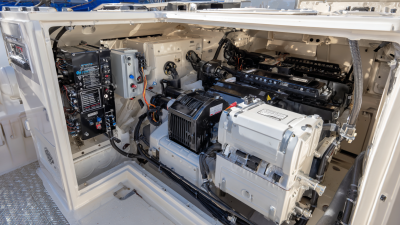

Ultimate Guide to Choosing the Perfect Marine Generators for Your Needs

-

Exploring the Innovation Behind Cummins Diesel Engines: Powering the Future of Transportation