How to Choose the Right Perkins Generator for Your Needs?

When selecting a Perkins generator, the choice can feel overwhelming. Each model has unique features and benefits. According to industry expert John Smith, “Choosing the right Perkins generator is about understanding your specific power needs.” His insight emphasizes the importance of assessing your requirements.

Consider the power output necessary for your operations. A power outage can lead to loss and frustration. Understanding peak loads and average usage is essential. Different businesses have different demands. A construction site may require more power than an office building. Knowing how much you need narrows down your options.

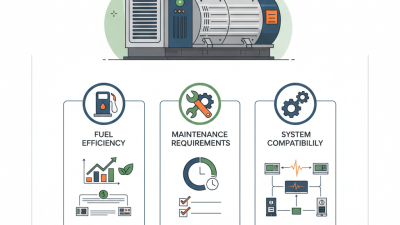

Also, think about fuel efficiency and maintenance needs. Some models may require more frequent servicing. Higher fuel consumption can increase operational costs. Don’t overlook noise levels, especially in urban areas. Evaluate where and how the generator will be used. Even with careful planning, unexpected challenges may arise. Reflect on your choices, and be ready to adapt as necessary.

Understanding Perkins Generators and Their Applications

When considering generators, it's important to understand their applications. These machines provide reliable power in various settings. For construction sites, they ensure that heavy machinery operates smoothly. In remote areas, they can supply much-needed electricity for homes and businesses.

Tip: Assess your power needs carefully. Calculate your total wattage requirements before making a choice. A generator that’s too small may fail during peak use. Conversely, an oversized generator can lead to wasted energy and increased costs.

Perkins generators serve diverse industries. From healthcare facilities needing continuous power to events requiring temporary setups, they fit different roles. It’s crucial to recognize the specific environment in which you'll use the generator. Understand the features that matter most for your application.

Tip: Consider fuel efficiency and noise levels. Some generators are quieter, which may be essential in residential areas or for events. Ensure the generator can handle your unavoidable usage peaks without compromise. Do thorough research to find the right balance between performance and efficiency.

Power Output Comparison of Perkins Generators

Identifying Your Power Requirements and Load Needs

Identifying your power requirements is a crucial step when selecting a generator. Start by determining the total wattage your appliances need. Compile a list of devices you plan to power. This may include lights, heaters, or heavy machinery. Be mindful of starting and running wattages. For instance, a refrigerator requires more power to start than to run. This can impact your decision significantly.

Consider your peak load needs. Peak load refers to the maximum amount of power you will use at any given time. It’s not just about what you might need generally. Think about high-demand scenarios, like during a power outage. Your generator should handle everything running simultaneously without issues.

Reflecting on your space and usage is essential too. A larger generator often means more fuel consumption. That may not suit everyone. Check how often you'll actually use it and for what duration. Will you need portability, or will a stationary unit suffice? These nuances can help narrow down your options and ensure a suitable choice for your unique needs.

Evaluating Generator Specifications and Features

Choosing the right generator requires understanding specifications. Generators vary in power output, efficiency, and features. A report from the Generator Manufacturers Association states that the right power output should match your needs. For example, a 5 kW generator is ideal for basic home use. Larger setups might need up to 20 kW, especially in commercial applications.

When evaluating generators, consider noise levels and fuel consumption. Many users overlook sound emissions. Reports suggest noise levels under 60 dB are optimal for residential areas. Additionally, fuel efficiency impacts long-term costs. A generator consuming less fuel may save you money over time.

**Tip:** Analyze your power needs carefully. A disconnect between your consumption and the generator’s output can lead to inefficiency. Pay attention to features, too. Automation, portability, and safety features can enhance usability. Optimal features are worth the extra investment.

**Tip:** Regular maintenance is crucial. Neglecting this can lead to performance drops. Some generators lose efficiency over time, often due to unattended upkeep. Keep an eye on oil levels and filters for best performance.

Considering Fuel Types and Efficiency Ratings

When choosing a generator, fuel types and efficiency ratings are key. Different fuels can significantly impact your operational costs and environmental footprint. Diesel, natural gas, and propane are common options. Each has unique benefits. Diesel engines often provide better torque and are widely used in heavy-duty applications. However, they can be louder and produce more emissions.

Efficiency ratings also matter. A generator with a high efficiency rating will consume less fuel for the same output. This means lower costs over time. Yet, high efficiency doesn’t always equate to high performance. Some might struggle with specific loads or operating conditions. It's wise to evaluate your unique power needs thoroughly. Analyze how much energy you really need. This could prevent overpaying for a unit that exceeds requirements.

Another aspect to consider is maintenance. Higher efficiency models may require specific maintenance practices. If not maintained properly, performance can decline quickly. Keep an eye on the manufacturer’s guidelines. Overlooking details may lead to costly repairs. Reflecting on these elements can help you make a more informed choice.

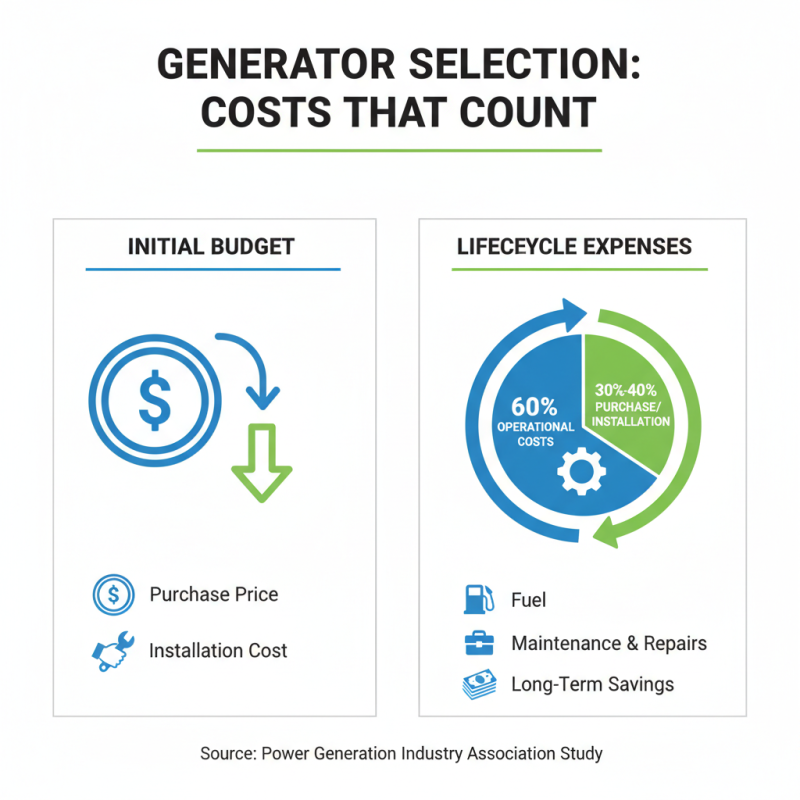

Assessing Budget and Maintenance Costs for Long-term Use

When selecting a generator, budget and maintenance costs are crucial factors. A study from the Power Generation Industry Association indicates that operational costs can account for over 60% of the total lifecycle expense. This hefty number emphasizes the importance of choosing wisely. A generator with a lower initial purchase price might not be cost-effective if it demands expensive upkeep.

Maintenance costs vary significantly. Regular servicing can cost from $100 to $500 per year. Inadequate maintenance may lead to abrupt failures, resulting in downtime. Statistics show that unplanned outages can increase operational costs by 30%. Owners should consider not just the fuel and oil but also parts replacement, labor, and service schedules.

Furthermore, the generator's efficiency affects its long-term usage. A unit that runs at optimal efficiency will lower fuel consumption. According to the Energy Efficiency Report, even a 10% improvement boosts savings on running costs. Evaluating these hidden costs aids in prudent decision-making. Buyers need to carefully assess whether they can manage these ongoing expenses over time.

Related Posts

-

Top Reasons to Choose Perkins Generator for Your Power Needs in 2025

-

Maximize Your Power Supply: The Unmatched Reliability of Perkins Generators for Every Need

-

2025 Top 10 Perkins Diesel Engines for Efficient Performance and Reliability

-

2026 How to Maintain a Cummins Diesel Engine for Optimal Performance?

-

Maximizing Efficiency: The Ultimate Guide to Choosing a Kubota Diesel Generator for Your Needs

-

How to Choose the Best Diesel Powered Generator for Your Needs