Yanmar Diesel Generator Tips for Efficient Operation and Maintenance?

When it comes to reliable power solutions, the Yanmar diesel generator stands out. These generators are known for their durability and efficiency. However, to maximize their performance, proper operation and maintenance are crucial.

Effective use requires attention to several key aspects. Regular inspections can prevent minor issues from escalating. Clean fuel and oil filters ensure optimal engine function. Moreover, understanding load requirements helps avoid overloading the generator.

Yet, many users overlook these details. Inadequate maintenance can lead to unexpected breakdowns. It's essential to reflect on past experiences and adjust practices accordingly. By implementing these tips, Yanmar diesel generator owners can enhance longevity and performance.

Understanding Yanmar Diesel Generators and Their Components

Yanmar diesel generators are reliable power sources for various applications. They consist of several key components, including the engine, alternator, and control panel. Understanding each part can enhance operation and maintenance. The engine converts fuel into mechanical energy. The alternator takes this energy and produces electricity. Regular checks of these components can prevent downtime.

To maintain efficiency, clean the air and fuel filters regularly. Dirty filters can restrict airflow and reduce performance. Check the oil level before each use. Low oil can lead to engine damage. Observe any unusual noises or vibrations. These can be signs of underlying issues that need immediate attention.

Monitoring fuel quality is crucial. Contaminated fuel can cause starting problems and decreased efficiency. Replace fuel filters as needed. Sometimes, older containers can introduce impurities. As with any machinery, it’s easy to overlook minor issues. Staying proactive can save time in the long run.

Yanmar Diesel Generator Tips for Efficient Operation and Maintenance

| Component | Maintenance Schedule | Tips for Efficiency | Common Issues |

|---|---|---|---|

| Air Filter | Every 250 hours | Clean or replace regularly | Clogging |

| Oil Filter | Every 500 hours | Change with oil | Reduced engine performance |

| Fuel Filter | Every 1000 hours | Use quality fuel | Fuel contamination |

| Cooling System | Every 100 hours | Check coolant levels | Overheating |

| Battery | Monthly | Keep terminals clean | Battery failure |

Best Practices for Operating Yanmar Diesel Generators Efficiently

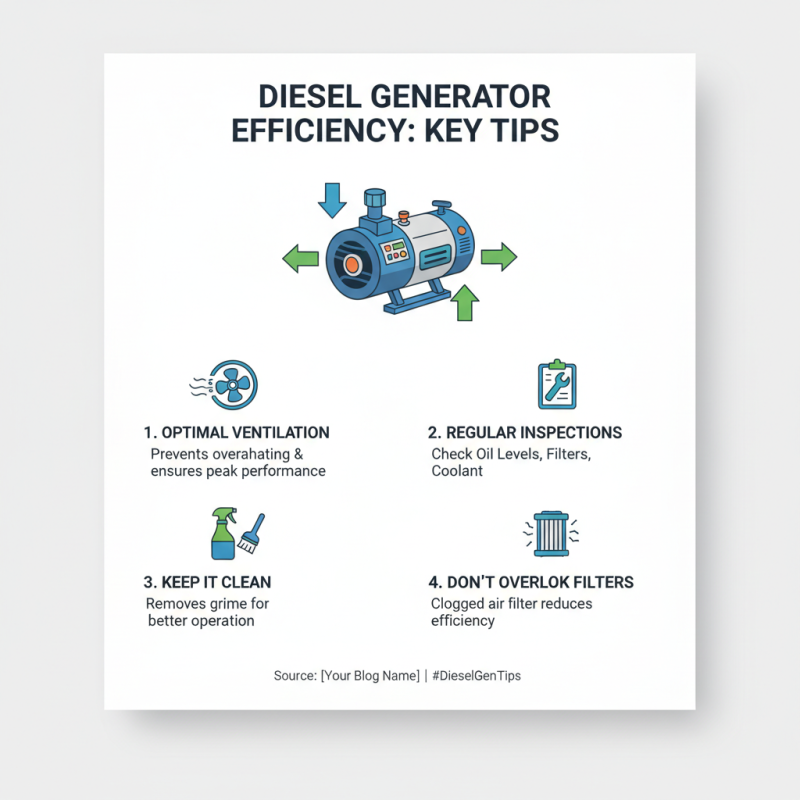

When operating diesel generators, efficiency is key. Start by ensuring proper ventilation. This prevents overheating and ensures optimal performance. Regular inspections are crucial. Check oil levels, filters, and coolant. A clean generator runs better, but cleaning can be messy. Don’t overlook the small details. A clogged air filter can reduce efficiency.

Fuel quality matters. Use clean, high-grade fuel for better combustion. Contaminated fuel may lead to operational issues. It’s a simple step but often ignored. Listen to the machine. Unusual noises or vibrations can signal problems. Ignoring these can lead to costly repairs later.

Regular maintenance helps too. Create a schedule and stick to it. Change the oil and filters routinely. Monitoring usage hours is essential. Sometimes, it’s easy to forget. Keeping a log can help you stay on track. Remember, a little attention now prevents major headaches down the line.

Regular Maintenance Tasks for Longevity of Diesel Generators

Regular maintenance is vital for the longevity of diesel generators. Over time, components can wear down. Keeping up with essential tasks can improve performance. Here are some tips to follow.

Checking the oil level is crucial. Low oil can cause damage. Change the oil regularly to keep the engine lubricated. Clean or replace air filters too. Dust can build up quickly, affecting efficiency.

Fuel quality matters. Using clean fuel prevents clogging. Inspect fuel filters often. They should be changed every few months based on usage. Lastly, battery maintenance is essential. Ensure connections are tight and corrosion-free. A neglected battery can lead to unexpected failures.

Common Issues and Troubleshooting Tips for Yanmar Generators

Maintaining a diesel generator requires attention to common issues. One frequent problem is fuel contamination. Dirt and water can enter the fuel system and disrupt performance. A 2022 industry report noted that 32% of generator failures trace back to fuel quality. Regularly inspecting fuel filters is essential. It can prevent potential complications and ensure a smoother operation.

Another common issue is improper cooling. Overheating can damage internal components. Routine checks on the coolant level are crucial. Surprisingly, many operators overlook this step. A study revealed that over 40% of generators fail to maintain optimal cooling, leading to costly repairs. Keeping the cooling system clean and functional is a must.

Electrical problems also arise from loose connections or corroded terminals. These issues may seem minor but can significantly impact performance. Inadequate electrical connections can result in power fluctuations, which is a common concern among users. Regular inspection of electrical components is vital for long-term reliability. Addressing these problems early can save time and resources.

Safety Precautions for Operating Yanmar Diesel Generators

Operating Yanmar diesel generators safely is crucial for optimal performance. Proper maintenance reduces risks and enhances longevity. Regularly inspect fuel lines. Check for leaks or damages. A small leak can lead to serious hazards. Statistics show that improper maintenance is a leading cause of generator failures, accounting for over 30% of all generator issues.

Ensure ventilation in the generator area. Poor ventilation can lead to carbon monoxide buildup. This is a deadly risk, as carbon monoxide is odorless and invisible. In fact, the CDC reports that exposure to high levels can cause serious health problems, including death. Also, never operate a generator indoors. This is a common mistake that can easily be avoided.

Always use the appropriate protective gear when handling fuel or performing maintenance. Gloves, goggles, and masks can prevent accidents. Despite this, many operators neglect these precautions, risking injuries. Routine checks are essential but often overlooked. Without diligence, minor problems can escalate into major failures. Keeping maintenance logs can help track issues. This can make a difference in safety and operational efficiency.

Yanmar Diesel Generator Efficiency Analysis

Related Posts

-

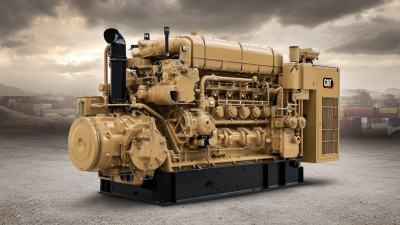

Understanding the Power Behind Caterpillar Diesel Generators: Efficiency, Reliability, and Applications

-

Top 10 Benefits of Diesel Motors: Why They’re the Best Choice for Your Needs

-

2025 Top 5 Caterpillar Diesel Generators: Powering Industries with 15% More Efficiency

-

Top Reasons to Choose Perkins Gensets for Your Power Generation Needs

-

10 Best Diesel Powered Generators for Reliable Power Solutions

-

Understanding the Role of Industrial Diesel in Sustainable Energy Transition