How to Power Diesel Engines for Optimal Performance and Efficiency

In the pursuit of maximizing the performance and efficiency of diesel engines, industry experts continually emphasize the importance of proper management and technology. Renowned diesel power specialist Dr. Emily Carter notes, "To truly power diesel engines at their peak, one must understand not only the mechanics but also the intricacies of fuel management and maintenance." This insight underlines the significance of a holistic approach in harnessing the full potential of diesel power.

The operational efficiency of diesel engines is heavily influenced by various factors including fuel quality, engine tuning, and regular maintenance schedules. As diesel technology evolves, it is crucial for operators and engineers alike to stay informed about innovative practices that can enhance engine capabilities. Dr. Carter's research highlights innovative fuel additives and advanced diagnostics systems that can drastically improve engine longevity and performance.

By integrating best practices and cutting-edge technology, stakeholders in the diesel industry can ensure that they are not only optimizing performance but also promoting sustainable use of resources. This commitment to excellence in power diesel applications can lead to significant advancements in efficiency, driving the entire sector forward.

Understanding Diesel Engine Basics for Performance Optimization

Understanding the fundamentals of diesel engines is crucial for achieving peak performance and efficiency. Diesel engines operate by compressing air to achieve ignition, resulting in a more fuel-efficient combustion process compared to gasoline engines. This efficiency is reflected in various industry reports, which indicate that diesel engines can achieve up to 30% greater fuel economy than their gasoline counterparts. According to the U.S. Department of Energy, diesel engines typically offer a lower carbon dioxide emission profile, producing approximately 15-20% less CO2, which highlights their environmental benefits alongside their operational efficiency.

To optimize diesel engine performance, it is essential to focus on factors such as fuel quality, maintenance practices, and tuning. Studies have shown that high-quality diesel fuel, with lower sulfur content, can significantly enhance engine efficiency by promoting cleaner combustion and reducing deposits within the engine. Regular maintenance, including timely oil changes and filter replacements, can also improve operational reliability and efficiency. Furthermore, tuning the engine to align with optimal operating conditions, including adjusting the air-fuel ratio and ensuring proper turbocharger function, can maximize both power output and fuel economy, leading to a more sustainable and cost-effective operation.

How to Power Diesel Engines for Optimal Performance and Efficiency

| Parameter | Optimal Range | Impact on Performance |

|---|---|---|

| Fuel Type | Ultra-Low Sulfur Diesel (ULSD) | Improved combustion efficiency, reduced emissions |

| Oil Quality | API CI-4 or better | Enhances engine longevity, protects against wear |

| Air Intake | Clean with optimal flow | Increases power output, improves fuel efficiency |

| Cooling System | Maintained at 180-220°F | Prevents overheating, maintains optimal performance |

| Turbocharger Boost | 10-15 psi | Increases engine power and torque |

| Maintenance Frequency | Every 5,000 - 7,500 miles | Ensures optimal performance and reduces downtimes |

Key Factors Affecting Diesel Engine Efficiency and Power Output

When considering the efficiency and power output of diesel engines, several key factors come into play. One of the most significant is the fuel quality; studies show that high cetane number fuels lead to better combustion efficiency and reduced emissions. According to the U.S. Department of Energy, optimizing fuel injection timing can enhance engine performance by as much as 10-15%. This highlights the importance of using the right fuel and maintaining proper fuel systems to achieve optimal engine operation.

Another crucial aspect is the engine's thermal efficiency, which is influenced by its combustion design. Recent reports from the International Council on Clean Transportation indicate that advancements in turbocharging and intercooling technologies can increase thermal efficiency considerably, making engines not only more powerful but also more environmentally friendly. Proper maintenance, including regular checks on air filters and exhaust systems, plays a vital role as well; on average, well-maintained diesel engines can achieve a fuel efficiency improvement of approximately 5-15%. By focusing on these factors, diesel owners can significantly enhance their engines' performance and longevity.

Best Practices for Fuel Selection and Management in Diesel Engines

Selecting the right fuel for diesel engines is critical not only for performance but also for ensuring efficiency throughout the engine's operational life. According to the American Petroleum Institute, the quality of diesel fuel can significantly affect engine performance, fuel efficiency, and emissions. High-quality fuels with lower sulfur content minimize deposits and promote better combustion, leading to improved engine life and reduced maintenance costs. Additionally, using fuels with optimized cetane numbers, generally above 50, enhances ignition quality, resulting in smoother operation and higher efficiency.

Monitoring and managing fuel quality is equally essential. The National Renewable Energy Laboratory conducted studies indicating that regular fuel testing and filtration can lead to a 10-15% increase in engine efficiency. Bacterial contamination in fuel tanks can cause serious engine issues, making regular maintenance and the use of biocides important. Furthermore, proper storage conditions and periodic turnover of fuel can prevent degradation and maintain fuel integrity. By adopting these fuel selection and management best practices, operators can realize substantial gains in diesel engine performance and longevity while also contributing to reduced environmental impact.

Diesel Engines - Fuel Efficiency and Performance Over Varied Fuel Types

Maintenance Strategies for Enhancing Diesel Engine Performance

Maintaining a diesel engine is crucial for optimizing its performance and efficiency. Regular maintenance not only extends the engine's lifespan but also enhances fuel efficiency, reducing operational costs in the long run. A key maintenance strategy is to keep up with regular oil changes, as clean oil lubricates engine components effectively and prevents wear and tear. Additionally, inspecting and replacing fuel filters regularly helps to ensure that the engine receives a clean fuel supply, which is essential for optimal performance.

Tips: Always check the manufacturer's recommendations for maintenance schedules and follow them closely. Keeping a detailed log of maintenance activities can help you stay organized and proactive.

Another important aspect is monitoring the cooling system. Overheating can lead to severe engine damage, so it’s vital to regularly check coolant levels and replace old or degraded coolant. Ensure that the radiator and hoses are in good condition and free of leaks. This proactive approach to cooling system maintenance will help retain engine efficiency, even under high load conditions.

Tips: Before long trips or heavy usage, perform a thorough inspection of the cooling system. Consider investing in a thermal imaging camera to spot issues that may not be visible to the naked eye. Regular engine diagnostics can also provide early warnings of potential problems, allowing for timely interventions.

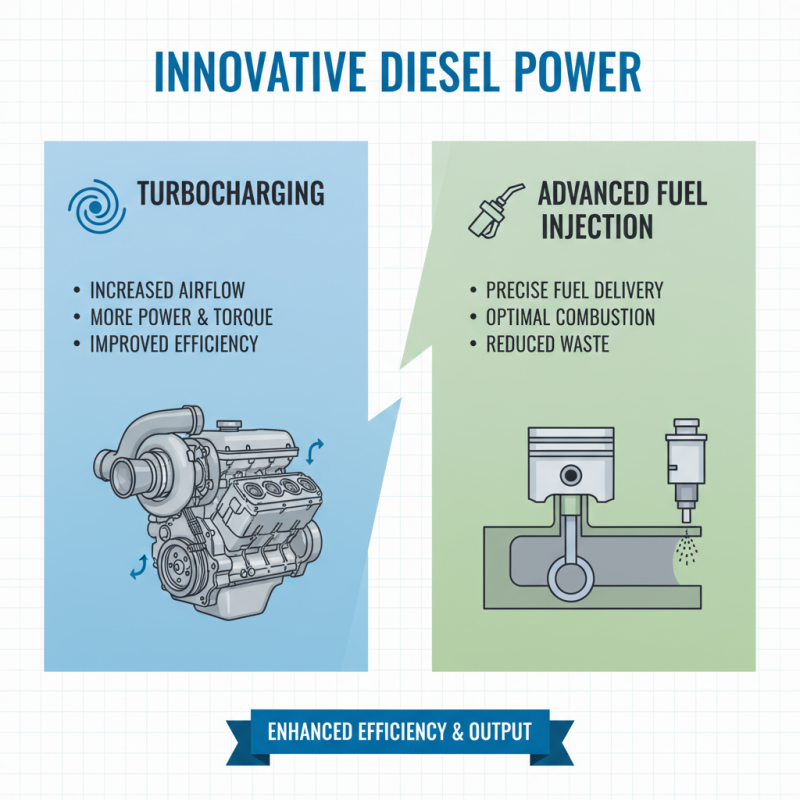

Innovative Technologies to Boost Diesel Engine Efficiency and Output

Innovative technologies have revolutionized the way diesel engines operate, enhancing both their efficiency and output. One of the foremost advancements is the introduction of turbocharging systems, which allows engines to inhale more air and burn more fuel. This results in increased horsepower and torque without significantly raising fuel consumption. Additionally, the integration of advanced fuel injection systems improves combustion efficiency by delivering fuel in precise quantities at optimal timings, minimizing waste and maximizing energy conversion.

Tips: Regular maintenance is crucial for optimal performance. Ensuring that fuel filters are changed and injectors are clean will prevent performance dips and enhance efficiency. Moreover, using high-quality lubricants can significantly reduce friction and wear, leading to a smoother operation and extended engine life.

Another promising technology is the adoption of exhaust after-treatment systems. These systems, including selective catalytic reduction (SCR) and diesel particulate filters (DPF), not only reduce harmful emissions but also contribute to improved engine performance by maintaining cleaner combustion environments. When these systems are well-maintained, they can help achieve greater fuel economy and power output, proving essential for modern diesel applications.

Tips: Monitor the health of after-treatment systems regularly; clogged filters can lead to increased back pressure, impairing performance. Implementing periodic diagnostics will ensure these systems are functioning as intended, safeguarding both efficiency and compliance with environmental standards.

Related Posts

-

Unleashing Power and Efficiency with Kohler Diesel Engines in Modern Machinery

-

Top 10 Power Diesel Engines for Unmatched Performance and Reliability in 2023

-

Understanding the Role of Industrial Diesel in Sustainable Energy Transition

-

2025 Top 10 Perkins Diesel Engines for Efficient Performance and Reliability

-

Maximizing Efficiency: The Ultimate Guide to Choosing a Kubota Diesel Generator for Your Needs

-

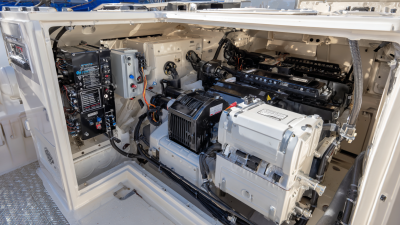

Ultimate Guide to Choosing the Perfect Marine Generators for Your Needs