2026 How to Maintain a Cummins Diesel Engine for Optimal Performance?

Maintaining a Cummins diesel engine is crucial for achieving top performance. The reliability of these engines makes them popular in various applications. However, ensuring they run efficiently requires dedicated care.

Regular maintenance tasks, like oil changes and filter replacements, are vital. Neglect can lead to reduced efficiency and costly repairs. Even minor issues, if overlooked, can escalate quickly. For instance, a clogged air filter limits airflow, harming performance.

To keep your Cummins diesel engine operating optimally, develop a robust maintenance schedule. Inspect fuel systems and check for leaks often. Address any abnormal sounds promptly. These actions can save you from unexpected breakdowns. A little attention goes a long way in enhancing engine longevity.

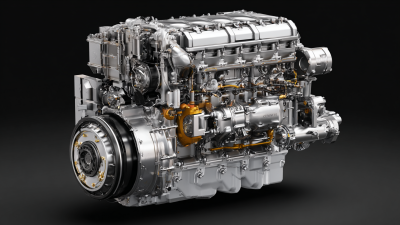

Understanding the Basics of Cummins Diesel Engines

Understanding the basics of diesel engines can enhance your maintenance efforts. Diesel engines are robust and powerful. They rely on compression for ignition, unlike gasoline engines. This fundamental difference means that they can run longer and often deliver higher torque.

Regular maintenance is crucial. Checking the oil regularly helps to keep the engine running smoothly. Dirty oil can harm engine components. Fuel quality also matters; using bad fuel can cause performance issues. Pay attention to any unusual noises or vibrations; they can indicate problems.

Cooling systems are essential for engine longevity. Overheating can lead to severe damage. Additionally, air filters should be inspected often. Clogged filters reduce efficiency and can hinder performance. Maintaining these aspects requires diligence, but the result is a more reliable engine. It's easy to overlook small details, but they can lead to bigger issues down the road.

2026 How to Maintain a Cummins Diesel Engine for Optimal Performance

Routine Maintenance Tasks for Cummins Diesel Engines

Routine maintenance is essential for maximum efficiency of diesel engines. A well-maintained engine can improve fuel efficiency by up to 10%, according to industry reports. Regular oil changes are crucial. Engine oil degrades over time, losing its lubricating properties. Aim to change it every 5,000 to 7,500 miles, depending on your engine specifications.

Tips: Check the oil level weekly. This can prevent serious engine damage before it starts.

Air filters also play a critical role. Clogged filters can restrict airflow, reducing performance. Inspect and replace them every 15,000 miles. This simple step can enhance engine efficiency significantly.

Remember, fuel quality matters. Poor quality fuel can harm injectors. Consider using a fuel additive to maintain injector cleanliness. It’s a proactive approach that more drivers should adopt.

Don't forget about coolant systems. Flushing the coolant every two years helps prevent overheating. An engine running hot can lead to failure. This often goes unnoticed until it’s too late.

2026 How to Maintain a Cummins Diesel Engine for Optimal Performance? - Routine Maintenance Tasks for Cummins Diesel Engines

| Maintenance Task | Frequency | Expected Duration | Notes |

|---|---|---|---|

| Oil Change | Every 5,000 miles | 1 hour | Use recommended oil type |

| Fuel Filter Replacement | Every 10,000 miles | 30 minutes | Check for water in fuel |

| Air Filter Inspection | Every 15,000 miles | 20 minutes | Replace if damaged or dirty |

| Coolant Check | Every 30,000 miles | 15 minutes | Ensure proper mixture |

| Belt Inspection | Every 20,000 miles | 10 minutes | Look for wear and tear |

Key Fluid Checks and Changes for Optimal Engine Performance

Maintaining a diesel engine requires keen attention to fluids. Fluid checks are crucial for optimal performance. Regular oil changes keep your engine running smoothly. Diesel engines depend on clean, high-quality oil to reduce wear and tear. It’s wise to check oil levels frequently, especially before major trips.

Coolant levels also deserve attention. An overheating engine can lead to severe damage. Always inspect the coolant reservoir for the correct fill level. Frequent checks will help you catch problems early. Replace the coolant according to the manufacturer's recommendations to avoid corrosion and maintain efficiency.

Fuel quality is another vital aspect. Contaminated diesel can cause performance issues. Make sure to use a fuel filter to eliminate impurities. Remember, a small oversight can lead to more significant problems down the line. Stay diligent with your fluid checks. This habit can extend the life of your diesel engine considerably.

Common Troubleshooting Tips for Diesel Engine Issues

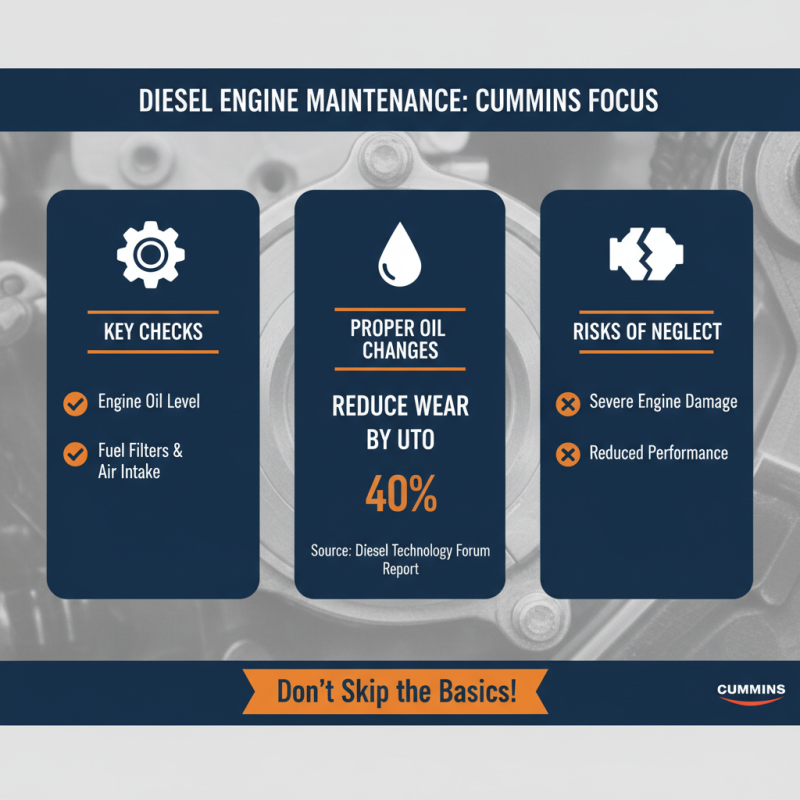

Diesel engines, particularly Cummins models, require careful monitoring and maintenance. Common issues often arise from neglecting basic checks. Regularly examine engine oil levels, fuel filters, and air intakes. A report from the Diesel Technology Forum indicates that proper oil changes can reduce wear by up to 40%. Skipping these tasks can lead to severe damage.

Another frequent issue is poor fuel quality. Contaminated fuel can clog injectors and filters, leading to reduced efficiency. A study showed that 25% of diesel engine repairs are linked to fuel problems. Running on low-quality diesel affects performance and longevity. Always use quality fuel and consider adding a fuel treatment.

Overheating is also a critical concern. It can be prevented with regular inspections of the cooling system. Check coolant levels and hoses regularly. A well-maintained cooling system can improve engine lifespan. Neglecting it, however, can lead to costly repairs and replacements. Use a temperature gauge to monitor engine heat, ensuring optimal function.

Advanced Maintenance Techniques for Long-Term Reliability

Maintaining a diesel engine for optimal performance isn't just about routine checks. Advanced techniques can significantly enhance its longevity and reliability. Start with regular oil changes, which are crucial. High-quality oil keeps the engine clean and reduces wear. Monitor the oil level consistently. Neglecting this can lead to severe damage.

Air filters are often overlooked. A clean air filter boosts efficiency and horsepower. Check it frequently, especially in dusty environments. Fuel quality matters too. Use premium diesel to prevent injector issues. Contaminated fuel can lead to costly repairs. Always inspect fuel lines for leaks.

Cooling systems deserve attention as well. Make sure the coolant is at the right levels. Overheating can lead to warping. Inspect hoses for cracks and signs of wear; this can prevent sudden failures. Regularly check belts for tension. A loose belt can cause loss of power and increase engine strain. Addressing these areas proactively saves money and time in the long run.

Related Posts

-

Exploring the Innovation Behind Cummins Diesel Engines: Powering the Future of Transportation

-

Exploring the Efficiency and Reliability of Diesel Powered Generators in Emergency Power Supply Systems

-

Maximize Your Power Supply: The Unmatched Reliability of Perkins Generators for Every Need

-

Understanding the Role of Industrial Diesel in Sustainable Energy Transition

-

Top 10 Power Diesel Engines for Unmatched Performance and Reliability in 2023

-

Top 10 Benefits of Using a 15kw Diesel Generator for Your Power Needs