10 Essential Tips for Maintaining Your Yanmar Motor: Maximize Performance!

Maintaining your Yanmar motor is crucial for ensuring optimal performance and longevity. As a dependable power source for various marine and agricultural applications, a well-maintained Yanmar motor can enhance efficiency while reducing the risk of unexpected breakdowns. Proper care not only extends the life of your motor but also ensures that it operates at peak performance, giving you confidence whether you are on the open water or working the fields.

In this guide, we will share 10 essential tips to help you maintain your Yanmar motor effectively. These tips are designed for both new and experienced users, providing practical advice to troubleshoot common issues and perform routine maintenance. From regular oil changes to monitoring cooling systems, understanding these maintenance practices can help prevent costly repairs and keep your Yanmar motor running smoothly. Prioritizing maintenance will ultimately maximize your investment and ensure that your Yanmar motor continues to deliver the performance you expect.

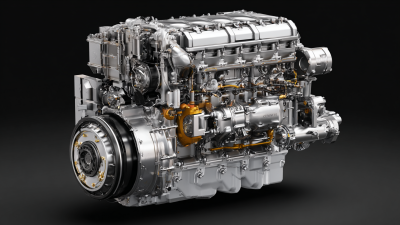

Understanding Your Yanmar Motor: Key Components and Functions

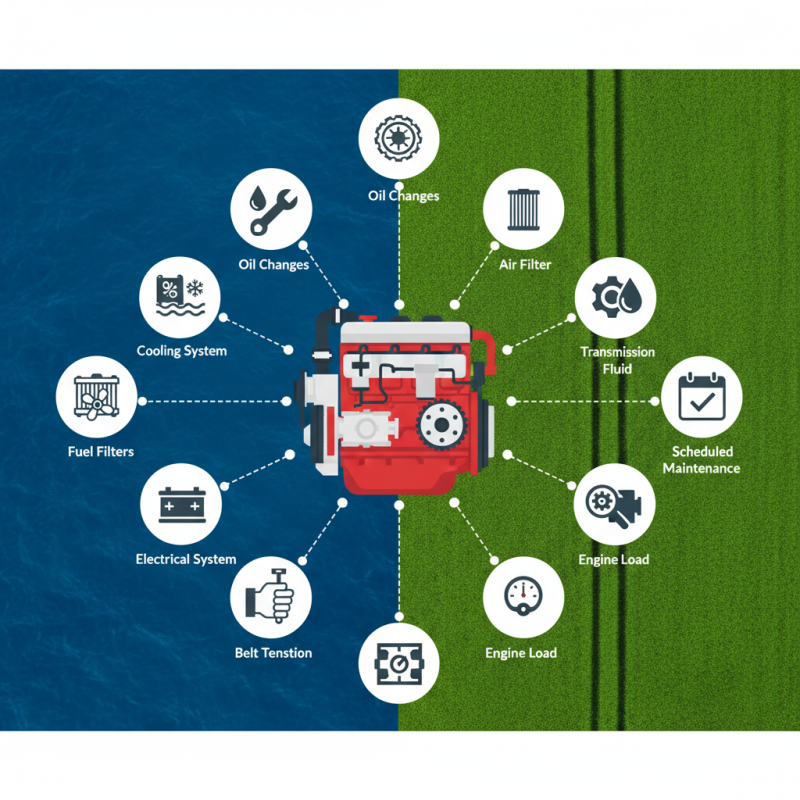

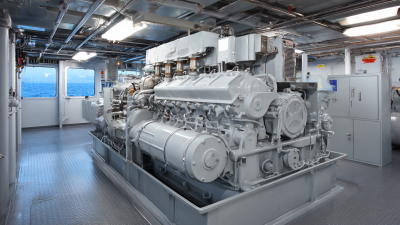

Understanding the key components and functions of your marine motor is essential for optimal performance and longevity. A typical marine motor consists of crucial parts such as the engine, transmission, fuel system, cooling system, and electrical system. Each of these components plays a significant role in ensuring the motor operates smoothly and efficiently. For example, according to a report by the American Boat and Yacht Council, a well-maintained cooling system can reduce the risk of overheating, which is one of the leading causes of engine failure in marine motors.

The fuel system is also vital, as it directly affects the engine's overall performance and fuel efficiency. Data indicates that improperly maintained fuel systems can result in a 10-15% decrease in fuel efficiency. Additionally, regular checks of the electrical components, including batteries and wiring, are necessary to prevent potential failures. Industry standards suggest that routine inspections and timely replacements can enhance the reliability of your motor, ultimately leading to improved performance on the water. Understanding these key components not only helps in maintaining your motor but also enhances your overall boating experience.

Performance Metrics of Yanmar Motors

This bar chart represents various performance metrics of Yanmar motors. Each metric is weighted on a scale of 0 to 100, highlighting areas such as fuel efficiency, max power output, torque, maintenance intervals, and noise levels. Regular maintenance can help enhance these metrics for optimized performance.

Regular Maintenance Schedule: Keeping Your Motor in Top Shape

To keep your Yanmar motor in peak condition, adhering to a regular maintenance schedule is crucial. According to industry experts, routine maintenance can enhance engine longevity by up to 50%. This frees you from costly repairs and downtime, ensuring that your motor operates efficiently for extended periods. A consistent schedule for checks and servicing can help address minor issues before they escalate into serious problems, making it essential to set reminders for important maintenance tasks.

One vital tip is to change the engine oil and filter at recommended intervals—typically every 100 hours of operation or once a season, depending on usage. Fresh oil not only lubricates engine components but also helps in removing contaminants that can lead to wear and tear. Additionally, regularly inspect and clean the fuel system. Dirty fuel injectors can significantly reduce power output and efficiency. Keeping filters clean and checking for leaks can prevent performance issues while maintaining optimal fuel efficiency.

Another crucial aspect of maintenance is monitoring the cooling system. Regularly inspect hoses, clamps, and coolant levels to avoid overheating. An estimated 40% of engine failures are related to cooling system issues, emphasizing the importance of vigilance. Furthermore, consider annual exhaust system checks to prevent dangerous emissions and ensure safe operation. By following these maintenance tips diligently, you can maximize the performance and lifespan of your motor.

10 Essential Tips for Maintaining Your Yanmar Motor: Maximize Performance!

| Tip Number | Maintenance Tip | Frequency | Details |

|---|---|---|---|

| 1 | Check Engine Oil | Every 100 hours | Inspect oil level and condition; change if necessary. |

| 2 | Inspect Fuel Filters | Every 200 hours | Replace or clean filters to ensure fuel flow. |

| 3 | Clean Air Filter | Every 100 hours | Ensure optimal airflow to the engine. |

| 4 | Examine Belts and Hoses | Every 200 hours | Replace worn or damaged belts and hoses. |

| 5 | Inspect Cooling System | Every 300 hours | Check coolant levels and condition; flush if needed. |

| 6 | Battery Maintenance | Monthly | Check terminals for corrosion and ensure proper charge. |

| 7 | Check Propeller Condition | Every season | Inspect for damage; replace if necessary. |

| 8 | Inspect Electrical Connections | Every 6 months | Ensure connections are tight and corrosion-free. |

| 9 | Test Emergency Shut-Off | Monthly | Ensure the system functions properly in emergencies. |

| 10 | Follow Manufacturer's Guidelines | Ongoing | Always refer to the user manual for specific maintenance needs. |

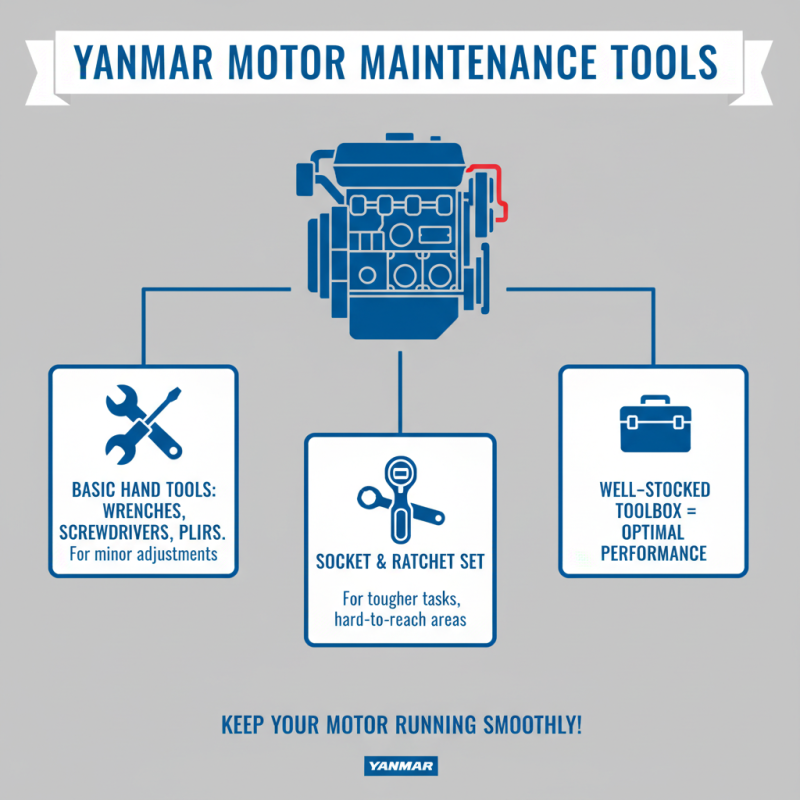

Essential Tools for Yanmar Motor Maintenance: A Comprehensive List

When it comes to maintaining your Yanmar motor, having the right tools at your disposal is crucial for effective upkeep and performance optimization. A well-stocked toolbox can make routine maintenance tasks more manageable and ensure that your motor runs smoothly. Start with basic hand tools such as wrenches, screwdrivers, and pliers, which will assist you in tightening bolts and making minor adjustments. Additionally, invest in a set of socket and ratchet tools for more complicated tasks, allowing for greater torque and easier access to hard-to-reach areas of the motor.

In addition to hand tools, consider including a few specialized instruments in your maintenance arsenal. A multimeter is invaluable for diagnosing electrical issues, while an oil filter wrench is essential for safe and hassle-free oil changes. A fuel system cleaner can help maintain optimal fuel flow and combat potential clogging. Furthermore, a coolant tester ensures that your motor’s temperature regulation is functioning correctly. By equipping yourself with these essential tools, you’ll be well-prepared to tackle maintenance challenges and keep your Yanmar motor performing at its best.

Common Issues and Troubleshooting Tips for Yanmar Motors

When it comes to maintaining your engine, understanding common issues and effective troubleshooting strategies is key to maximizing performance. Regular maintenance can help mitigate problems such as overheating, which is a prevalent issue in marine engines. According to industry reports, nearly 30% of engine failures stem from inadequate cooling, leading to significant damage and costly repairs. Regularly checking coolant levels, inspecting the heat exchanger for fouling, and ensuring proper water flow can help maintain optimal operating temperatures.

Another common problem is fuel system failure, which often results from contamination and injector clogging. Industry studies indicate that a staggering 40% of engines suffer from fuel-related issues, underscoring the importance of fuel quality and system cleanliness. Implementing a regimen of routine fuel filter changes and utilizing high-quality fuel can greatly enhance engine longevity and efficiency. Additionally, keeping an eye on symptoms such as rough idling or reduced power can help you catch fuel system problems early, preventing further complications and ensuring your engine runs smoothly.

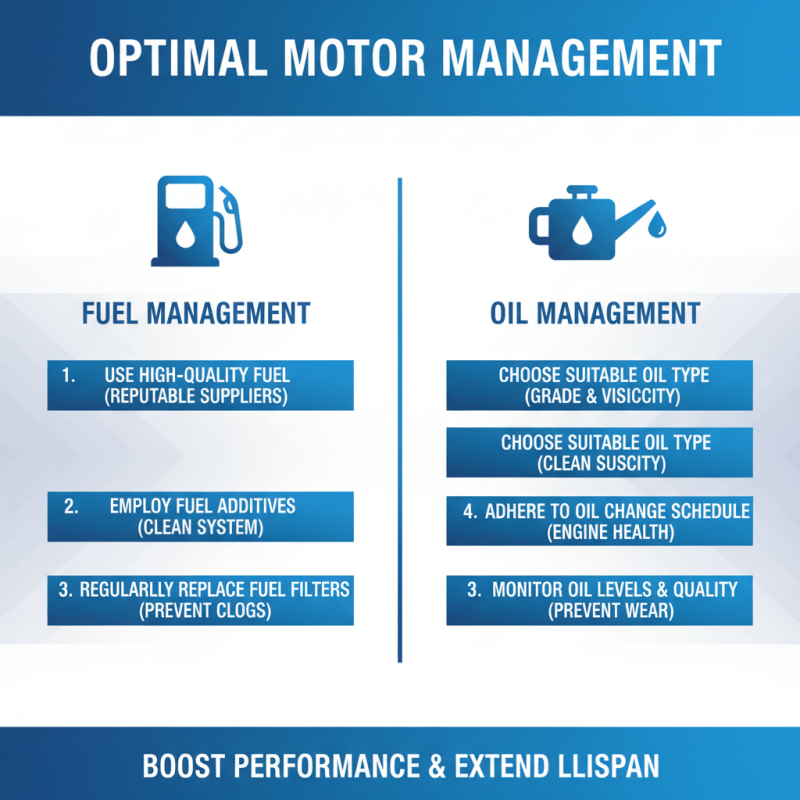

Best Practices for Fuel and Oil Management in Your Yanmar Motor

Maintaining optimal fuel and oil management for your motor is crucial in enhancing performance and extending its lifespan. Start by ensuring that you are using high-quality fuel. Contaminated or low-grade fuel can lead to engine issues, so it's essential to source your fuel from reputable suppliers. Additionally, consider using fuel additives that can help clean the fuel system and improve combustion efficiency. Regularly check and replace fuel filters to avoid clogs that can hinder performance.

When it comes to oil management, choosing the right oil type is essential for optimal engine function. Always refer to your engine’s specifications when selecting oil; this ensures compatibility and protects against excessive wear. Regular oil changes are vital, as old oil can lose its effectiveness and lead to increased friction and heat. Monitoring the oil level frequently and topping it up as necessary will prevent damage from low oil conditions. Finally, keep an eye on oil quality; if it appears dark or has a burnt smell, it's time for a change. By following these best practices, you can ensure your motor operates smoothly and efficiently.

Related Posts

-

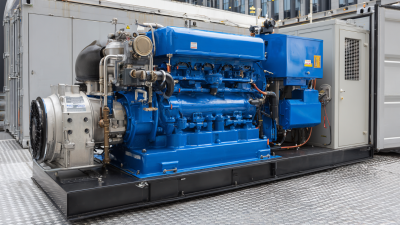

Top 10 Benefits of Using Yanmar Generators for Your Power Needs

-

What is a Marine Diesel Generator and How Does it Work for Your Needs

-

Why Your Business Needs a Lister Generator for Efficient Marketing Strategies

-

Exploring the Innovation Behind Cummins Diesel Engines: Powering the Future of Transportation

-

Exploring the Efficiency and Reliability of Diesel Powered Generators in Emergency Power Supply Systems

-

2025 Top 5 Caterpillar Diesel Generators: Powering Industries with 15% More Efficiency