How to Choose the Right Industrial Diesel Generator for Your Business Needs

In today’s competitive landscape, selecting the right industrial diesel generator is crucial for businesses that rely on consistent power to operate efficiently. According to John Smith, a leading expert in the field of energy solutions, “A well-chosen industrial diesel generator not only ensures operational continuity but also contributes to overall cost savings.” This insight underscores the importance of understanding the unique power requirements of your business before committing to a purchase.

When considering options for an industrial diesel generator, it's essential to assess various factors such as load capacity, fuel efficiency, and maintenance needs, all while keeping in mind the specific operational demands of your industry. The right generator can mean the difference between seamless productivity and costly downtimes. Engaging with industry specialists can further aid in making informed decisions, ensuring that the generator aligns with both current and future business needs.

Ultimately, the right industrial diesel generator can serve as a reliable backbone for operations, delivering the necessary power to keep your business running smoothly and effectively adapting to changing circumstances. Making a thorough and informed choice will not only protect your investment but also enhance your operational efficiency in the long run.

Understanding Your Power Requirements for an Industrial Diesel Generator

When selecting the right industrial diesel generator for your business needs, it's essential to first understand your power requirements. According to the International Energy Agency, the demand for reliable power sources in industrial settings has been steadily increasing, with many sectors reporting a critical reliance on backup power systems. The first step is to assess your total power load, which includes not only machinery but also auxiliary equipment, lighting, and HVAC systems. A comprehensive load assessment ensures that your generator can handle peak demands without overloading or underperforming.

**Tips:** Consider using load calculators available from industry resources that can help you quantify your current and future power requirements. Additionally, keep in mind that the efficiency of your generator can be influenced by factors such as altitude and temperature, which can affect performance if not adequately factored into your calculations.

Another vital aspect to consider is the duration of power outages in your area. A report by the U.S. Energy Information Administration indicates that the average duration of outages has increased in recent years, making it prudent for businesses to invest in generators that not only meet immediate power requirements but also provide sufficient operational time during prolonged outages. This evaluation will guide you in choosing a generator with the right fuel capacity and runtime to keep your operations seamless.

**Tips:** Regularly review historical outage data relevant to your location to better understand potential risks and prepare accordingly. This data can be invaluable in determining the most appropriate generator size and specifications for your specific needs.

Evaluating Generator Types and Their Applications in Various Industries

When selecting the right industrial diesel generator for your business, it is crucial to evaluate the various types available and their specific applications across different industries. The most common types include portable generators, standby generators, and prime power generators. Portable generators, ideally suited for construction sites and outdoor events, provide temporary power where utility sources are unavailable, often delivering 5 to 20 kW of output. Standby generators are designed for applications requiring a reliable backup during power outages, particularly in healthcare and data centers, offering seamless transition with output commonly ranging from 10 kW to over 2 MW.

In industries such as manufacturing and oil and gas, prime power generators are vital as they supply continuous electricity where grid power is unreliable or non-existent. These generators usually produce between 50 kW to several megawatts, making them essential for supporting heavy machinery and processes. According to the International Energy Agency (IEA), the global demand for diesel generators is expected to grow by approximately 6% annually, driven by emerging markets that rely heavily on these systems for energy independence and stability. Evaluating the specific power needs, load requirements, and operational hours is key to selecting the most suitable generator type for your operations while ensuring compliance with industry regulations and efficiency standards.

Industrial Diesel Generators Power Output by Type

This bar chart illustrates the power output of various types of industrial diesel generators, highlighting their suitability for different business needs. The portable generator is suitable for smaller applications, while industrial generators are needed for larger, more demanding operations.

Key Features to Consider When Selecting a Diesel Generator

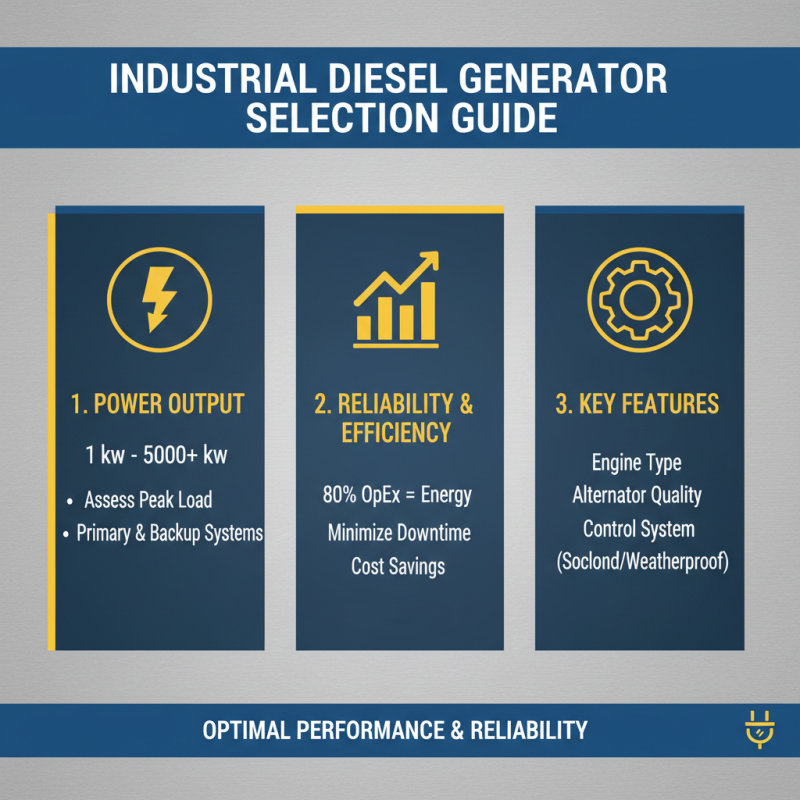

When selecting a diesel generator for your industrial needs, several key features should be considered to ensure optimal performance and reliability. Firstly, power output is paramount. Industrial diesel generators typically range from 1 kW to over 5000 kW, depending on the application. It’s essential to assess your business's peak power requirements, factoring in both the primary and backup systems, to avoid under-sizing or over-sizing the generator. According to a report by the International Energy Agency, industries heavily depend on reliable power sources, with up to 80% of operational costs attributed to energy consumption. Therefore, an accurate assessment of your energy needs is critical.

Another essential feature is fuel efficiency. Diesel generators are favored for their longer operational hours and lower fuel consumption compared to their gasoline counterparts. Improved fuel efficiency translates to decreased operational costs, as shown in a study by the Diesel Technology Forum, which indicates that newer diesel technologies can achieve up to 25% better fuel economy than older models. Additionally, consider the noise levels and emissions, as regulations around noise pollution and environmental impact continue to tighten. Selecting a generator with lower decibel ratings and reduced emissions can help comply with local regulations and maintain a positive community relationship.

**Tips:** Always consult with a power specialist to tailor your generator selection based on real-time usage patterns and future scaling plans. Furthermore, reviewing maintenance schedules and support services offered can greatly influence long-term operational reliability and efficiency. Investing time in assessing these key features will lead to a more resilient and cost-effective power solution for your business.

Assessing Fuel Efficiency and Operating Costs of Diesel Generators

When evaluating the fuel efficiency and operating costs of industrial diesel generators, several factors come into play. According to the U.S. Energy Information Administration (EIA), diesel generators can achieve thermal efficiencies of approximately 35% to 45%. This high efficiency makes them a popular choice for many businesses, particularly where continuous power supply is crucial. Changes in fuel prices can significantly impact overall operating costs; thus, maintaining an understanding of current diesel prices is essential. For instance, fluctuations in crude oil prices can lead to a ripple effect that alters diesel fuel costs, emphasizing the importance of choosing generators equipped with advanced fuel management systems to optimize consumption.

Additionally, operating costs are not solely determined by fuel efficiency. Routine maintenance, which accounts for approximately 5-10% of total operating expenditures, plays a critical role in determining long-term costs and reliability. A report from the International Energy Agency (IEA) suggests that businesses with well-maintained equipment can reduce their overall fuel consumption by up to 10% compared to those with poor maintenance practices. Hence, investing in a diesel generator with lower emissions and higher operational uptime can significantly influence the total cost of ownership. Careful assessment of these factors will help businesses make informed decisions that align with both budgetary constraints and sustainability goals.

How to Choose the Right Industrial Diesel Generator for Your Business Needs

| Generator Model | Power Output (kW) | Fuel Consumption (L/h) | Fuel Efficiency (kW/L) | Operating Cost ($/h) |

|---|---|---|---|---|

| DXG1000 | 1000 | 200 | 5.0 | 150 |

| DXG800 | 800 | 160 | 5.0 | 120 |

| DXG500 | 500 | 100 | 5.0 | 75 |

| DXG1200 | 1200 | 240 | 5.0 | 180 |

| DXG300 | 300 | 60 | 5.0 | 50 |

Maintenance and Support Considerations for Long-term Generator Usage

When selecting an industrial diesel generator, maintenance and support are critical factors that directly impact the generator's longevity and performance. Regular maintenance ensures that the generator operates efficiently and reduces the risk of unexpected failures. Key maintenance tasks should include regular oil changes, fuel system checks, and battery inspections. Establishing a maintenance schedule helps businesses avoid costly downtime, as routine maintenance can uncover potential issues before they escalate.

In addition to routine maintenance, it is crucial to consider the level of support provided by the chosen generator supplier. A reliable supplier will offer comprehensive support services, including troubleshooting assistance, parts availability, and on-site repair options. It's beneficial to establish a service agreement that outlines the frequency of maintenance visits and the response time for urgent repairs. By prioritizing maintenance and support, businesses can ensure that their diesel generators remain operational, ultimately contributing to uninterrupted power supply and overall business efficiency.

Related Posts

-

Exploring the Efficiency and Reliability of Diesel Powered Generators in Emergency Power Supply Systems

-

2025 How to Choose the Best Small Diesel Engine for Your Needs

-

Top 10 Benefits of Using a 15kw Diesel Generator for Your Power Needs

-

Top 10 Benefits of Diesel Motors: Why They’re the Best Choice for Your Needs

-

Ultimate Guide to Choosing the Perfect Marine Generators for Your Needs

-

Unleashing Power: How Generator Sets Are Transforming Energy Solutions for Businesses