Top 10 Tips for Choosing the Best Diesel Generator for Your Needs

Choosing the right diesel generator is crucial for both residential and commercial applications, as the demand for reliable power sources continues to grow. According to industry reports, the global diesel generator market is expected to reach approximately $23 billion by 2025, driven by increased infrastructure development and the need for uninterrupted power supply. When selecting a diesel generator, factors such as load capacity, fuel efficiency, and durability must be considered. Among the many options available, the kubota diesel generator has gained popularity for its robust performance and reliability, making it a preferred choice for many users.

In light of the increasing prevalence of natural disasters and power outages, investing in a quality diesel generator can provide peace of mind. Furthermore, a well-chosen generator can lead to significant cost savings over time, as modern units are designed for maximum efficiency and lower emissions. Understanding the specific requirements of your application, such as standby versus prime power needs, will play a vital role in your decision-making process. By following expert recommendations and analyzing market trends, you can ensure that your investment in a diesel generator, like the kubota diesel generator, aligns with your energy needs and sustainability goals.

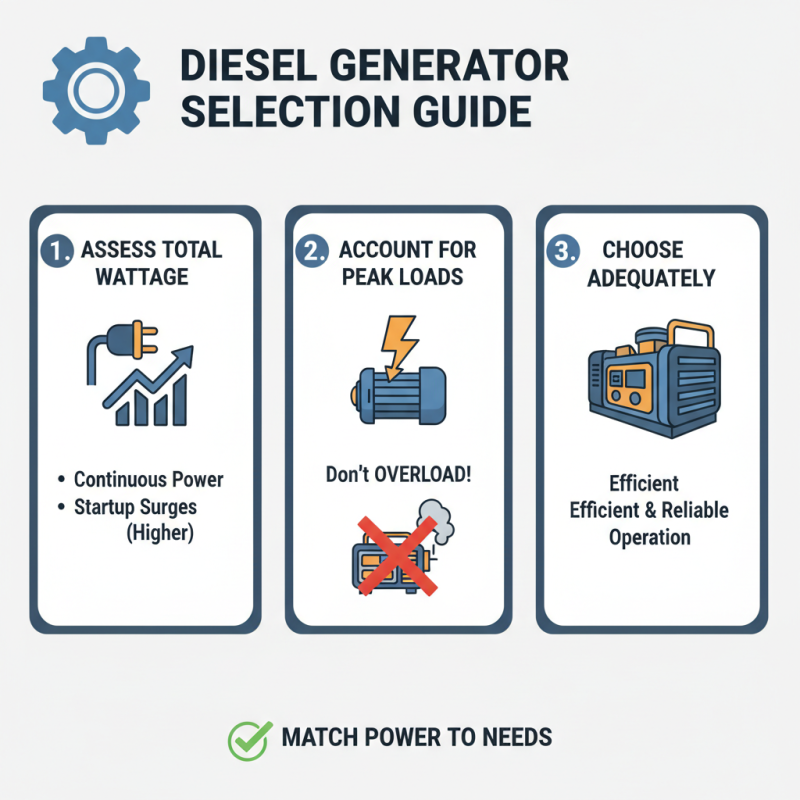

Understanding Your Power Requirements for a Diesel Generator

Understanding your power requirements is crucial when selecting the best diesel generator for your needs. Start by assessing the total wattage your equipment will require. This includes not only the continuous power needed for your devices but also accounting for any startup surges, which can be significantly higher. By having a clear understanding of your power needs, you can choose a generator that adequately meets these demands without overloading it, which could lead to inefficiencies or premature failure.

When evaluating your requirements, consider both the types of equipment you intend to power and the duration of usage. For instance, if you plan to run heavy machinery or multiple appliances simultaneously, you’ll need to calculate their combined wattage. Additionally, if you anticipate using the generator for extended periods, opt for a unit with higher fuel efficiency and a larger fuel capacity to minimize downtime.

Tip: Always leave some headroom in your calculations. A general rule is to select a generator that provides at least 20% more wattage than your total calculated needs. This ensures that your generator can handle unexpected loads and maintains longevity. Moreover, think about the environment where the generator will be used. Factors such as intended location, potential noise restrictions, and weather conditions can influence your final decision. This thorough approach enables you to confidently choose the best diesel generator tailored to your specific power needs.

Evaluating Generator Ratings: KVA vs. KW and Their Importance

When selecting a diesel generator, one of the critical considerations is understanding generator ratings, specifically KVA (kilovolt-amperes) and KW (kilowatts). KVA is a measurement that refers to the apparent power output of the generator, encapsulating both the real power (KW) and reactive power (KVAR). In practical terms, this means that while a generator might be rated at 100 KVA, its actual usable power will depend on the power factor, which is typically around 0.8 for most applications, thereby providing approximately 80 KW of effective power. This distinction is vital because selecting a generator solely based on KVA might lead to underperformance if the KW output is not aligned with the electrical load requirements.

Moreover, understanding the relationship between KVA and KW is particularly crucial in industries that rely heavily on machinery and equipment that require a specific power output to operate efficiently. According to data from the International Energy Agency, industrial sectors that utilize diesel generators significantly report energy efficiency improvements of up to 15% when generator ratings are accurately matched to power needs. By evaluating these ratings carefully, businesses can avoid overspending on unnecessarily large generators or risking operational failures due to inadequate power supply. Therefore, it is essential to thoroughly assess the power requirements of your applications before deciding on a generator's size and rating.

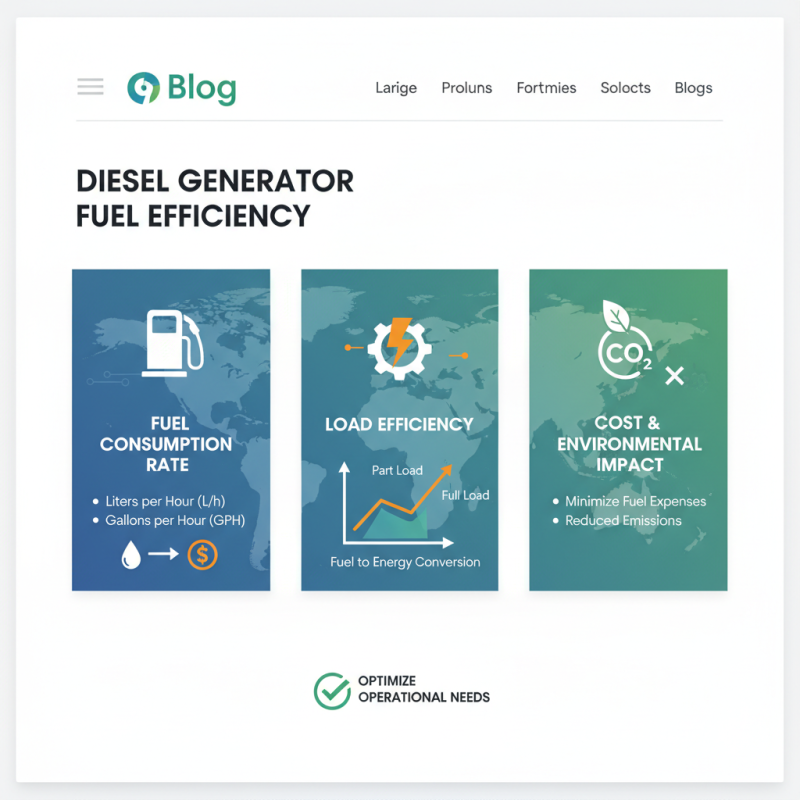

Assessing Fuel Efficiency: Key Metrics and Industry Standards

When choosing the best diesel generator, assessing fuel efficiency is paramount. Fuel efficiency relates directly to how much fuel is consumed during operation, influencing both operational costs and environmental impact. Key metrics to consider include the generator's fuel consumption rate, measured in liters per hour (L/h) or gallons per hour (GPH), and load efficiency, which indicates how effectively the generator converts fuel into electrical energy under various load conditions. Understanding these metrics allows users to compare different generators and identify models that align with their operational needs while minimizing fuel expenses.

Industry standards also play a crucial role in evaluating fuel efficiency. Look for generators that meet or exceed established benchmarks set by regulatory bodies, which often include performance ratings and emissions standards. Certifications such as ISO 8528, which outlines performance criteria for diesel engines, are valuable indicators of reliability and energy efficiency. Additionally, consider the generator's operational flexibility; a unit that can efficiently handle varying loads often proves more economical in the long run. Overall, focusing on these fuel efficiency metrics and industry standards will help ensure the selected generator not only meets immediate power needs but also operates economically and sustainably.

Importance of Noise Levels: Decibel Ratings and Compliance

When selecting a diesel generator, understanding noise levels is crucial to ensure compliance with local regulations and to meet your specific needs. Noise is measured in decibels (dB), and different applications have varying allowable noise thresholds. For instance, residential areas often impose stricter limits compared to industrial settings. It’s essential to consider where the generator will be used to select a model that not only fits your power requirements but also operates within acceptable noise limits.

Moreover, many modern diesel generators come equipped with noise reduction technology, significantly minimizing their acoustic footprint. When evaluating a generator, look for its decibel rating at a given load, typically provided in the specifications. Generators that produce sound levels below 60 dB are generally suitable for residential areas, while those that exceed this level may be best for remote or industrial locations. Being aware of these ratings helps ensure you choose a generator that will function effectively without disrupting your environment or violating noise ordinances.

Top 10 Tips for Choosing the Best Diesel Generator for Your Needs

| Model | Power Output (kW) | Noise Level (dB) | Compliance Standards | Fuel Tank Capacity (L) | Run Time (Hours) |

|---|---|---|---|---|---|

| Model A | 10 | 65 | EPA Tier 4 | 20 | 8 |

| Model B | 15 | 70 | EPA Tier 4 | 30 | 10 |

| Model C | 20 | 75 | CARB Compliant | 50 | 12 |

| Model D | 25 | 80 | EPA Tier 3 | 40 | 15 |

| Model E | 30 | 85 | CARB Compliant | 60 | 14 |

Maintenance Considerations: Lifespan and Service Intervals in Industry

When it comes to the longevity and reliability of diesel generators, maintenance considerations play a critical role. Regular service intervals are essential in maximizing the lifespan of these machines. According to industry standards, an average diesel generator can last anywhere from 10,000 to 30,000 hours depending on usage and maintenance practices (Data from the Diesel Engine Manufacturers Association). Regular maintenance checks, including oil changes every 150-500 hours, are vital to ensure optimal performance and to prevent premature wear and tear.

One crucial tip for selecting a diesel generator is to consider your specific power requirements and operational patterns. This involves understanding the expected load and choosing a generator that can comfortably handle it without constant strain. It's also important to schedule routine maintenance based on your generator's usage—high-utilization units may require more frequent service intervals to mitigate the risks of unexpected failures. Implementing a proactive maintenance schedule not only enhances reliability but also supports compliance with safety regulations, which can be crucial in many industrial applications.

Additionally, factoring in environmental conditions is essential. For instance, operating a generator in extreme temperatures can affect its performance and longevity. Regular inspections for wear and fuel quality can significantly improve the health of your generator. Overall, a well-maintained diesel generator not only extends its lifespan but also ensures that it operates efficiently, minimizing costly downtimes in your operations.

Diesel Generator Maintenance Considerations: Lifespan and Service Intervals

Related Posts

-

Maximizing Efficiency: The Ultimate Guide to Choosing a Kubota Diesel Generator for Your Needs

-

Top Reasons to Choose Perkins Gensets for Your Power Generation Needs

-

How to Choose the Right Kohler Diesel Engine for Your Needs

-

2025 Top 5 Caterpillar Diesel Generators: Powering Industries with 15% More Efficiency

-

The Ultimate Guide to Choosing the Right Small Diesel Generator for Your Needs

-

10 Best Diesel Powered Generators for Reliable Power Solutions