2025 How to Choose the Best Small Diesel Engine for Your Needs

Choosing the right small diesel engine for your specific needs can be a daunting task, especially with the numerous options available in today’s market. According to renowned industry expert Dr. John Smith, a leading authority on diesel technology, "Selecting the best small diesel engine is not just about power; it's about matching the engine's capabilities with your operational requirements." This statement highlights the critical importance of understanding both your application needs and the characteristics of the engine itself.

In recent years, small diesel engines have gained popularity due to their efficiency and reliability. They are commonly used in a variety of applications, including agricultural equipment, generators, and light-duty vehicles. However, with evolving technologies and diverse models, it is crucial for users to evaluate what features truly matter, such as fuel efficiency, torque, and maintenance demands. Each engine variant carries unique advantages and drawbacks, making informed decision-making essential for optimal performance and cost-effectiveness.

As we delve into the process of selecting the best small diesel engine, it will be imperative to consider both personal requirements and expert insights. By understanding the specific role a small diesel engine will play in your operations, you can make an educated choice that not only meets but exceeds your expectations.

Understanding the Basics of Small Diesel Engines: An Overview

When exploring the world of small diesel engines, it's essential to grasp the fundamental components and operations that differentiate these engines from their gasoline counterparts. Small diesel engines typically utilize a compression ignition process, which allows for higher fuel efficiency and reduced emissions compared to traditional gasoline engines. According to a report by the U.S. Environmental Protection Agency, diesel engines can be up to 30% more fuel-efficient than gasoline engines, making them an attractive option for various applications, including agriculture and small industrial machines.

Furthermore, understanding engine displacement and power output is critical for making an informed choice. Small diesel engines generally range from 1 to 5 liters in displacement, producing between 20 to 100 horsepower. Data from the Diesel Technology Forum suggests that the increasing demand for small diesel engines is driven by their capability to perform under heavy loads while maintaining lower operational costs. This versatility is particularly beneficial in sectors that require reliable and robust power solutions, where performance and sustainability are paramount.

In addition to efficiency and power, familiarity with maintenance requirements is vital for potential users. Small diesel engines often demand more rigorous upkeep due to the need for regular oil changes and fuel filter replacements. Industry experts recommend considering factors such as operating hours and workload intensity to determine the best engine maintenance schedule. This proactive approach not only enhances engine longevity but also ensures optimal performance throughout its service life.

Key Factors Influencing Diesel Engine Selection for Specific Applications

When selecting a small diesel engine for specific applications, several key factors must be considered to ensure the engine meets the intended requirements efficiently. First and foremost is the engine's power output, which should align with the demands of the application, whether it be for agricultural equipment, generators, or marine vehicles. Evaluating the torque characteristics is equally important, as different tasks may require varying torque levels at specific RPMs for optimal performance.

Another significant factor is the size and weight of the engine, particularly in mobile applications where space and weight constraints are critical. A compact design can facilitate easier installation and enhance maneuverability without compromising power or fuel efficiency. Additionally, the fuel consumption rate plays a vital role, as lower fuel usage can lead to cost savings over time. It is also essential to consider the operational environment; for instance, some engines are better suited for extreme temperatures, higher altitudes, or dusty conditions, which can affect longevity and reliability. By carefully analyzing these factors, users can select a small diesel engine that not only meets their performance needs but also supports sustainability and economic viability.

2025 Small Diesel Engine Selection Factors

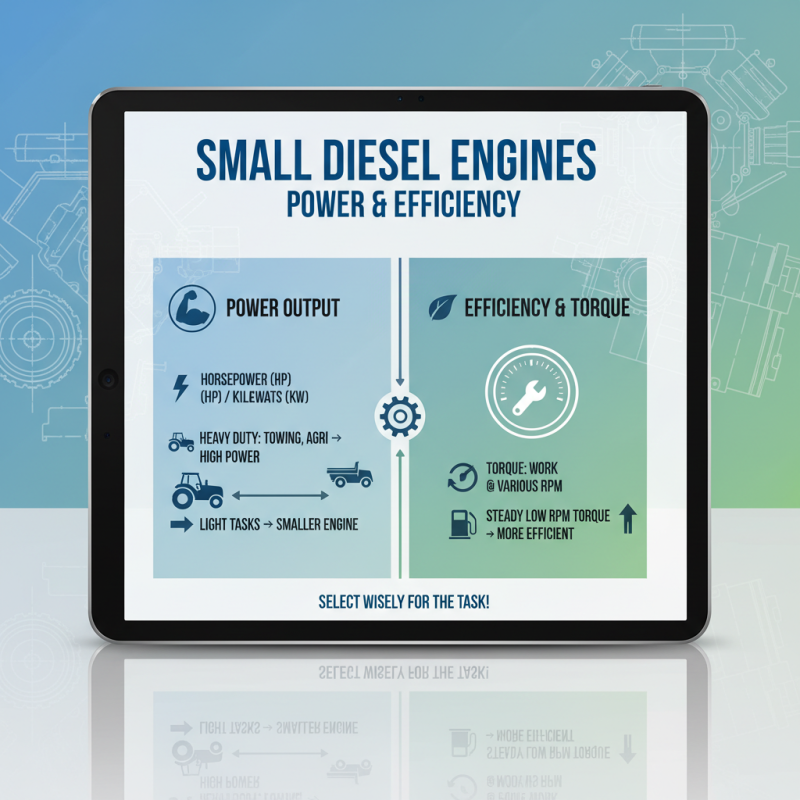

Comparative Analysis: Power Output and Efficiency of Small Diesel Engines

When selecting a small diesel engine, understanding the power output and efficiency is crucial. Power output, measured in horsepower or kilowatts, indicates how much work the engine can perform. For instance, if you require the engine for heavy-duty applications like towing or agriculture, a higher power output is essential. Conversely, for lighter tasks, a smaller engine may suffice. Analyzing the torque characteristics also helps, as it describes the engine's ability to perform work at different RPMs. Engines that provide steady torque at lower RPMs tend to be more efficient for such applications.

Efficiency should be evaluated through fuel consumption rates and thermal efficiency. Regularly understanding these metrics can help you choose an engine that not only meets your power requirements but also operates cost-effectively. It’s also beneficial to consider engine displacement and how it affects the engine's overall efficiency—larger engines often consume more fuel, while smaller engines may struggle with demanding tasks.

Tips: When narrowing down your options, create a checklist of your specific needs, including expected loads and operating conditions. Additionally, consider the long-term operational costs rather than just the initial purchase price. Consulting user reviews and expert opinions can provide further insight into the reliability and efficiency of the engines you’re considering.

Evaluating Fuel Consumption and Emissions: Industry Benchmarks

When evaluating small diesel engines for your needs, fuel consumption and emissions are two critical factors to consider. Industry benchmarks provide a useful reference point to assess the efficiency and environmental impact of various engines. Fuel consumption typically varies based on engine design, load characteristics, and operational practices. For effective selection, understanding the engine's performance in real-world applications is essential. Look for data that compares different models under similar conditions to get a clearer picture of how they will perform in your specific context.

Emissions are another vital aspect that has gained increasing scrutiny due to environmental regulations and sustainability goals. Small diesel engines must adhere to stringent emission standards, which regulate pollutants such as nitrogen oxides (NOx) and particulate matter (PM). Evaluating the emissions profile of an engine requires a keen eye for compliance with these standards, as well as an understanding of any advanced technologies employed to reduce harmful outputs. When choosing an engine, consider both the immediate emissions and the potential long-term impacts on air quality and regulatory compliance, ensuring alignment with both personal and organizational environmental objectives.

2025 How to Choose the Best Small Diesel Engine for Your Needs - Evaluating Fuel Consumption and Emissions: Industry Benchmarks

| Engine Model | Fuel Consumption (L/100km) | CO2 Emissions (g/km) | Power Output (HP) | Torque (Nm) |

|---|---|---|---|---|

| Model A | 5.8 | 150 | 75 | 200 |

| Model B | 6.2 | 160 | 85 | 210 |

| Model C | 5.5 | 145 | 70 | 190 |

| Model D | 6.0 | 155 | 80 | 205 |

Maintenance Considerations: Ensuring Longevity of Your Diesel Engine

Maintenance considerations play a crucial role in ensuring the longevity of your small diesel engine. Regular maintenance routines should begin with frequent oil changes, as diesel engines are particularly sensitive to oil quality. Using high-quality oil and replacing it at recommended intervals can help reduce wear and tear, enhance engine performance, and ultimately extend its lifespan. Additionally, monitoring the engine’s cooling system is essential. Regularly checking coolant levels and ensuring that the radiator is clean can prevent overheating, a common issue that can lead to significant damage over time.

Another vital aspect of diesel engine maintenance is air filtration. A well-maintained air filter prevents dust and debris from entering the engine, which can cause premature wear on critical components. It is advisable to inspect and replace the air filter regularly, especially in dusty environments. Furthermore, keeping an eye on fuel quality is essential; using clean, high-quality fuel can reduce the risk of injector issues and improve overall engine efficiency. By following these maintenance practices, you can enhance the reliability and durability of your small diesel engine, ensuring it meets your needs for years to come.

Related Posts

-

2025 Top Diesel Generator Options to Power Your Home and Business

-

Unleashing Power: How Generator Sets Are Transforming Energy Solutions for Businesses

-

Unleashing Power and Efficiency with Kohler Diesel Engines in Modern Machinery

-

Understanding the Power Behind Caterpillar Diesel Generators: Efficiency, Reliability, and Applications

-

Top 5 Reasons to Choose a Cat Diesel Generator for Your Power Needs

-

How to Choose the Right Kohler Diesel Engine for Your Needs