How to Choose the Right Kohler Diesel Engine for Your Needs

When it comes to selecting the ideal Kohler diesel engine for your specific applications, the decision-making process can be daunting due to the myriad options available in the market. As industry expert John Smith, a seasoned mechanical engineer and consultant, notes, "Choosing the right Kohler diesel engine is not just about power output; it's about understanding the demands of your project and matching them with the engine's capabilities." With such a diverse range of models, understanding your requirements is crucial to ensure optimal performance and efficiency.

In this guide, we will delve into the key factors to consider when selecting a Kohler diesel engine, including power needs, environmental considerations, and maintenance requirements. By examining these elements, we aim to equip you with the knowledge necessary to make an informed decision that aligns with your operational goals. Whether you are powering heavy machinery, agricultural equipment, or backup generators, the right Kohler diesel engine can significantly enhance productivity and reliability.

Understanding Your Power Requirements

When selecting the right Kohler diesel engine for your needs, understanding your power requirements is crucial. Different applications will demand different levels of power, which can significantly affect your choice. Consider factors such as the size of your equipment, the nature of the tasks it will perform, and the operating environment. These elements will help you determine the horsepower and torque specifications needed for optimal performance.

Tips: Before making a final decision, calculate the total load that will be powered by the engine. This includes not only the primary machinery but also any auxiliary systems that may draw power. It’s advisable to choose an engine that provides a margin above your calculated needs, ensuring reliability under varying conditions.

Another important consideration is the duty cycle of your application. If the engine will be running continuously or under heavy loads, a more robust option might be necessary. On the other hand, if your application is intermittent, a smaller engine may suffice. Tips: Always check the engine's efficiency ratings and maintenance requirements to ensure you choose a model that not only meets power needs but also fits your operational capabilities.

Evaluating Different Kohler Diesel Engine Models

When evaluating different Kohler diesel engine models, it's crucial to consider your specific application and operational requirements. Kohler offers a variety of models ranging from 6 to 100 HP, each tailored for various uses such as agricultural machinery, commercial equipment, or backup power generators. According to a recent industry report by Research and Markets, the global diesel engine market is projected to grow at a CAGR of 4.5% from 2021 to 2026, highlighting the rising demand for efficient and reliable diesel engines in various sectors.

One popular model, the Kohler KD Series, is known for its fuel efficiency and durability, making it an excellent choice for continuous-duty applications. With features like electronic fuel injection and advanced cooling systems, the KD Series can reduce fuel consumption by up to 20% compared to conventional models. Additionally, the KDW Series is designed with quieter operation in mind, featuring sound-dampening technology that complies with stringent noise regulations.

Knowing the specifications of each model and understanding performance metrics, such as torque curves and lifecycle costs, can help you select the right engine that aligns with both your operational needs and environmental standards.

Key Features to Consider When Choosing an Engine

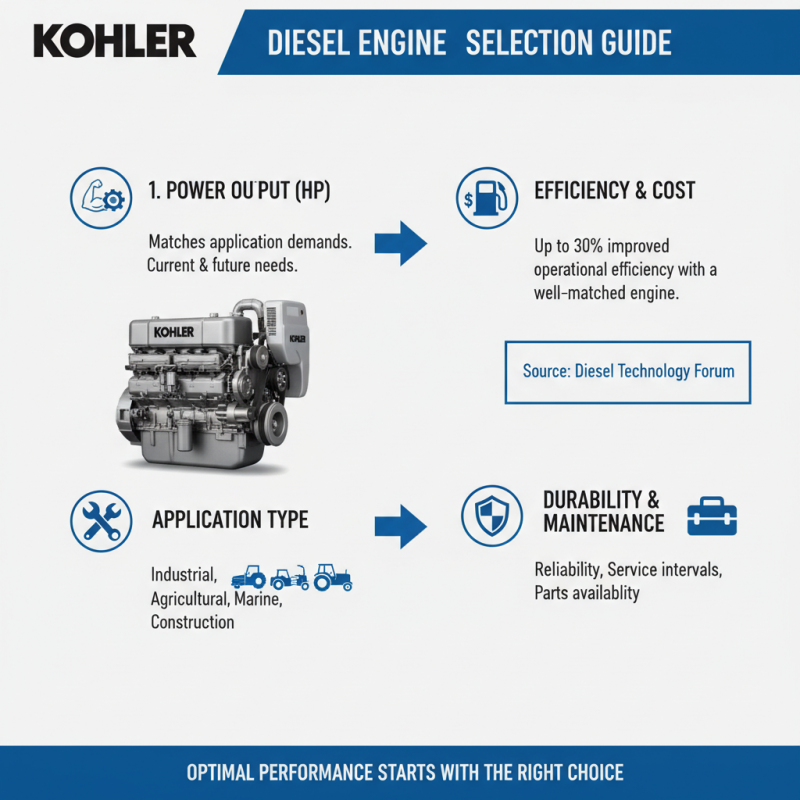

When selecting the right Kohler diesel engine for your specific needs, several key features should be considered to ensure optimal performance and efficiency. First, consider the engine's power output, measured in horsepower (HP), which directly influences its ability to handle the demands of your application. According to the Diesel Technology Forum, a properly matched engine can enhance operational efficiency by up to 30%, making it vital to choose an engine that not only meets your current power requirements but also anticipates future needs.

Another crucial factor is the engine's fuel efficiency, as this can dramatically affect your operating costs over time. Kohler's engines are engineered to achieve high fuel efficiency ratings, often exceeding 30% lower fuel consumption compared to older models. This aligns with the findings from the U.S. Department of Energy, which underscores that efficient engines can significantly reduce greenhouse gas emissions. Additionally, pay attention to the engine's maintenance requirements and warranty options, as reliable support and service play a pivotal role in minimizing downtime and maximizing productivity in demanding environments.

Application-Specific Factors for Diesel Engines

When selecting the right Kohler diesel engine for your specific application, it's crucial to consider application-specific factors that can significantly impact performance and efficiency. According to a recent report by the Diesel Technology Forum, diesel engines account for approximately 90% of heavy-duty vehicle power. This highlights the importance of understanding your operational context, whether it be construction, agriculture, or marine applications. Each use case requires different power outputs and fuel efficiency ratings, ultimately influencing your choice of engine.

For instance, if you are operating in a construction environment, you may need an engine that offers high torque at low RPMs to tackle heavy loads. A report from the Society of Automotive Engineers indicates that engines providing at least 120 horsepower with a torque of over 300 lb-ft are ideal for such applications. Conversely, for agricultural applications, a focus on lower emissions and fuel economy may lead you to select a different engine with advanced emission control technologies. Consequently, paying attention to these application-specific factors can not only optimize engine performance but also enhance operational efficiency and sustainability.

Choosing the Right Diesel Engine Based on Application Needs

Maintenance and Support Considerations for Diesel Engines

When choosing the right Kohler diesel engine, maintenance and support should be at the forefront of your decision-making process. Diesel engines require regular maintenance to ensure optimal performance and longevity. Consider the availability of maintenance services in your area, as well as the proximity of authorized service centers. Having reliable support can save you time and money, making your investment worthwhile.

Tips: Always review the maintenance schedule outlined by Kohler for your chosen engine model. Adhering to this schedule will help prevent major repairs down the line. Additionally, invest in high-quality replacement parts to ensure compatibility and reliability.

Another vital aspect is the availability of technical support. Check whether Kohler offers comprehensive resources such as manuals, troubleshooting guides, or online support. A robust support system can greatly enhance your experience, especially during unforeseen issues.

Tips: Joining online forums or local user groups can also provide valuable insights and tips from seasoned users, helping you navigate maintenance tasks more efficiently. Regular interaction with the community can lead to useful strategies and prevent potential problems before they arise.

Related Posts

-

Explore the Advantages of Kohler Diesel Engines for Heavy Duty Applications

-

10 Best Diesel Powered Generators for Reliable Power Solutions

-

Top 10 Benefits of Using Yanmar Generators for Your Power Needs

-

Maximizing Efficiency: The Ultimate Guide to Choosing a Kubota Diesel Generator for Your Needs

-

Understanding the Role of Industrial Diesel in Sustainable Energy Transition

-

Unleashing Power: How Generator Sets Are Transforming Energy Solutions for Businesses